Are you confident that your home’s fire safety system is functioning correctly? Interconnected smoke alarms are a crucial component of home safety, and testing their interlink function is vital to ensure they work together seamlessly in case of an emergency.

Statistics show that interconnected smoke alarms can reduce the risk of fatalities in a house fire by up to 50%. But how can you be certain that your system is working properly? This guide will walk you through the process of testing your smoke alarm system’s interlink function safely and effectively.

Understanding how to test your interlinked smoke alarms is essential for maintaining an effective early warning system. By following this guide, you’ll gain the confidence to ensure your home’s fire safety system is working correctly.

Key Takeaways

- Understand the importance of testing interlinked smoke alarms for optimal fire safety.

- Learn the procedures for testing smoke alarm interlink functions safely.

- Discover how to maintain an effective early warning system in case of fire emergencies.

- Gain confidence in your ability to properly maintain your home’s fire safety system.

- Ensure all units of your smoke alarm system communicate effectively with each other.

Understanding Interlinked Smoke Alarms

You can significantly enhance your home’s safety by understanding how interlinked smoke alarms work. Interlinked smoke alarms are connected wirelessly or through a hardwired system, creating a network of detection devices that communicate with each other.

What Are Interlinked Smoke Alarms?

Interlinked smoke alarms are designed to sound simultaneously when one detects smoke or fire, providing alerts throughout your property. This is particularly valuable in larger homes or multi-storey buildings.

Benefits of Interconnected Alarm Systems

The primary benefit of interconnected alarm systems is the extra time they provide for evacuation during a fire emergency. Statistics show that interconnected smoke alarms can reduce the risk of fatalities in a house fire by up to 50%. Modern interlinked systems can include different types of detectors working together to provide comprehensive protection.

Understanding your particular interlinked system is essential for proper testing and maintenance, ensuring it functions correctly in case of an emergency.

Preparing to Test Your Smoke-Alarm Interlink Function

Preparing to test your interlinked smoke alarms involves understanding whether you have hardwired or battery-operated units. This knowledge is crucial because the testing approach may vary slightly depending on your alarm type.

Identifying Your Alarm Type

To identify your alarm type, check if your smoke alarms are hardwired or battery-operated. Hardwired smoke alarms are connected directly to your home’s electrical system, while battery-operated units rely on batteries for power.

| Alarm Type | Power Indicator |

|---|---|

| Hardwired | Steady green LED light |

| Battery-Operated | Quick flash every 30-45 seconds |

Checking Power Status Indicators

For hardwired units, a steady green LED light typically indicates that the alarm is receiving AC power. Battery-operated units usually flash briefly every 30-45 seconds. However, it’s essential to consult your alarm’s manufacturer instructions to confirm the specific power indicators for your model.

Before testing, ensure you have access to all smoke alarms in your network and notify household members to prevent unnecessary panic. Consider scheduling regular testing dates on your calendar.

Step-by-Step Guide to Test Smoke-Alarm Interlink Function

Here’s a straightforward guide to testing your smoke alarm’s interlink function. Testing your smoke alarms regularly is crucial to ensure they are working correctly and can alert you in case of an emergency.

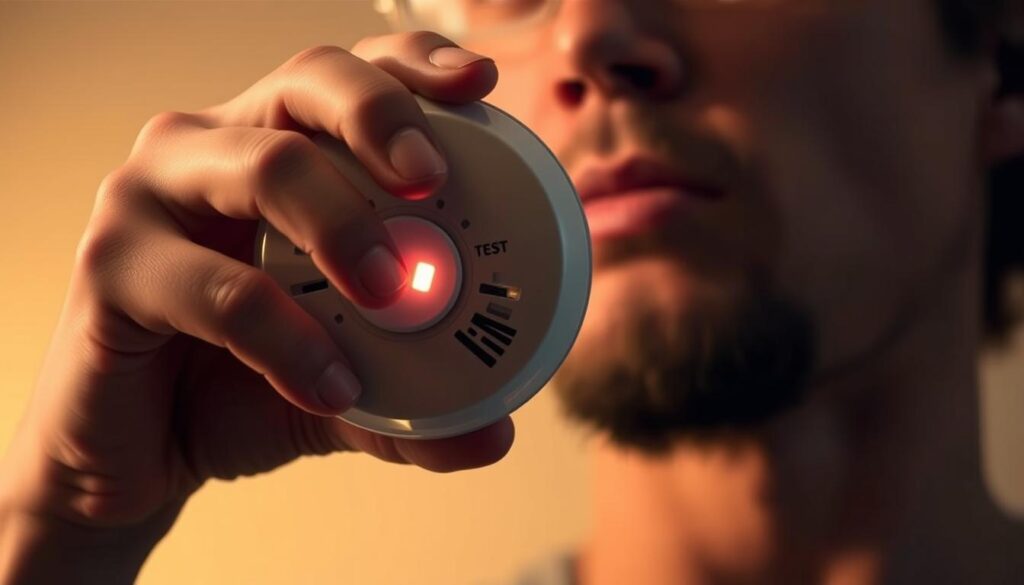

Locating the Test Button

The test button on most smoke alarms is typically located on the face or side of the unit. It may be labeled “Test,” “Test/Silence,” or “Test/Hush” depending on the model. To initiate the test, you need to press and hold this button.

Proper Testing Procedure

To test your smoke alarm’s interlink function, press and hold the test button on any single alarm unit for at least 5 seconds until it begins to sound. In a functioning interconnected system, all linked alarms should begin sounding within seconds.

What to Expect During a Successful Test

During a successful test, you should hear the same loud alarm sound from all units, indicating that the interlink circuitry is working correctly. For smoke-only models, the sound will stop immediately when you release the test button. For combination smoke and carbon monoxide detectors, the signal will continue from unit to unit.

Troubleshooting Common Interlink Issues

When your interlinked smoke alarms fail to function as expected, it’s crucial to identify the root cause of the issue. Interconnected smoke alarm systems are designed to provide comprehensive fire detection, but like any complex system, they can sometimes malfunction.

Identifying the Problem

If only one alarm is sounding during a test, it indicates a potential issue with the interconnect circuitry. This could be due to a problem with the wiring or the alarm itself.

- For hardwired systems, ensure all interconnect wires are properly connected and not damaged.

- Wireless interconnected alarms may suffer from range limitations or interference.

- Check that all alarms are receiving power, as those without power won’t respond to interconnect signals.

- Consult your alarm’s manual for model-specific troubleshooting steps.

Checking Interconnect Circuitry

The interconnect circuitry is a critical component of your smoke alarm system. Issues here can prevent alarms from communicating effectively. “A well-maintained interconnect system is vital for fire safety,” emphasizes the importance of regular checks.

If your smoke alarms are still under warranty and the interconnect function isn’t working, contact the manufacturer’s customer support for assistance. For complex issues, consider hiring professional fire safety services to diagnose and resolve the problem.

For further help or information, you can reach out to our customer care team. They are available to provide support and guide you through any concerns or inquiries you may have about your smoke alarm system, including those related to gas detectors and other related services.

Essential Safety Warnings

When testing your interlinked smoke alarms, it’s crucial to follow safety guidelines to avoid potential hazards. This ensures not only your safety but also the effectiveness of your alarm system.

Safety Precautions for Testing

Never use open flames, such as candles or lighters, to test your smoke alarms. This method can ignite nearby combustible materials and start a structure fire. Instead, use the test button specifically designed for this purpose, as it simulates smoke detection without exposing the alarm to actual smoke or heat.

Responding to Erratic Alarm Sounds

If your alarms produce erratic, intermittent, or unusually quiet sounds during testing, this may indicate a fault requiring immediate attention. Check your alarm’s warranty information to see if you are still within the warranty period. If so, contact the manufacturer’s product support for a replacement.

| Safety Tips | Description |

|---|---|

| Avoid Open Flames | Never use candles or actual smoke to test your smoke alarms, as this creates a genuine fire safety hazard. |

| Use Test Button | The test button simulates smoke detection without exposing the alarm to actual smoke or heat. |

| Check Warranty | If your alarm is faulty, check its warranty and contact product support for a replacement if necessary. |

For more information on home safety, including fire safety and prevention, visit Age UK’s guide on home safety. This resource provides valuable insights into maintaining a safe living environment.

Maintaining Your Interlinked Alarm System

Your interlinked smoke alarm system’s effectiveness relies heavily on regular testing and maintenance. To ensure your system remains in good working order, follow these guidelines.

Recommended Testing Frequency

Industry standards and fire safety experts recommend testing your smoke alarms weekly. This regular check helps ensure they remain in proper working condition. You can set up calendar reminders or associate testing with another weekly routine to maintain consistency in your fire safety maintenance.

Battery Replacement Guidelines

Replace batteries in battery-operated or battery-backup alarms at least once annually, or immediately when you hear the low-battery alert chirping sound. Many fire safety services suggest changing batteries when you adjust your clocks for daylight saving time as an easy-to-remember schedule.

Cleaning and Dust Removal

Gently vacuum your smoke alarms every six months using a soft brush attachment to remove dust and debris that can interfere with sensor operation. Never paint over smoke alarms as this can block the sensors and prevent proper detection of smoke particles.

Additional Maintenance Tips:

- Keep detailed maintenance records in a home safety account or log, noting dates of testing, battery replacements, and any issues encountered.

- For interconnected systems that include gas detection or carbon monoxide alarms, follow the specific maintenance instructions for these specialized units.

- Be aware that all smoke alarms, regardless of type, have a limited lifespan (typically 7-10 years) after which the entire unit should be replaced.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Test Smoke Alarms | Weekly | High |

| Replace Batteries | Annually or as needed | High |

| Clean Smoke Alarms | Every 6 months | Medium |

“Regular maintenance of your smoke alarm system is crucial for ensuring your safety in the event of a fire.”

By following these guidelines, you can ensure your interlinked smoke alarm system remains effective and reliable, providing you and your family with critical early warnings in case of a fire.

Conclusion

Regular testing of your interconnected smoke alarms is crucial for protecting lives and property. By following the testing procedures outlined in this guide, you can ensure your system provides the early warning needed during an emergency. Proper maintenance, including battery replacement and cleaning, extends the reliability of your alarm system. For additional guidance, refer to the manufacturer’s instructions available in the user manual.

Remember, never compromise on fire safety by neglecting regular tests or ignoring warning signs from your alarms. Consider setting up a home safety log to track maintenance and testing dates for all safety devices.