Are you confident that you’re applying the correct amount of torque to your projects? Using a torque wrench is crucial for ensuring the safety and performance of equipment in various industries, including automotive, construction, and DIY applications.

A torque wrench is a specialised tool designed to tighten fasteners such as nuts and bolts to a precise torque setting. However, if you’re not familiar with how to read the scale on your wrench, you may be compromising the integrity of your work.

Understanding how to correctly read the torque measurement on your tool is vital for preventing under-tightening and over-tightening, which can have serious consequences.

Key Takeaways

- Learn how to correctly read torque-wrench scales for precise tightening.

- Understand the importance of torque application for safety and performance.

- Discover the different types of torque wrenches and their specific reading methods.

- Avoid common mistakes when reading torque scales.

- Gain confidence in applying torque specifications for your projects.

Understanding Torque Wrenches and Their Importance

In various industries, torque wrenches play a pivotal role in maintaining the integrity of mechanical assemblies. A torque wrench is a tool that applies a specific amount of torque to a fastener, such as a bolt or nut. This is crucial for ensuring that the fastener is tightened to the correct specification, which is vital for the safety and performance of equipment.

What is a Torque Wrench?

A torque wrench is designed to apply a precise amount of torque, thus preventing both under-tightening and over-tightening of fasteners. This precision is essential for maintaining the structural integrity of mechanical components. Correct torque settings enhance the safety and performance of equipment, making it a critical tool in various industries.

Why Precise Torque Matters

Applying the correct amount of torque is crucial for the longevity and safety of mechanical assemblies. Under-tightened fasteners can work loose over time, potentially causing component failure or dangerous situations, especially in vehicles or heavy machinery. Conversely, over-tightened fasteners can strip threads or deform components. Manufacturers provide specific torque specifications for critical components based on extensive testing and engineering calculations. Following these specifications ensures optimal clamping force and proper gasket compression.

| Torque Application | Consequences of Incorrect Torque | Benefits of Correct Torque |

|---|---|---|

| Under-tightening | Fasteners work loose, potentially causing component failure | Ensures optimal clamping force |

| Over-tightening | Threads can be stripped, or components deformed | Prevents damage to components |

| Correct Tightening | – | Ensures proper gasket compression and correct preload on bearings |

As emphasised by industry experts, precise torque is not just a matter of mechanical advantage but also of safety.

“The correct application of torque is fundamental to the reliability and safety of mechanical systems.”

This underscores the importance of using a torque wrench to achieve the precise torque needed for various applications, from automotive to industrial machinery.

Different Types of Torque Wrenches

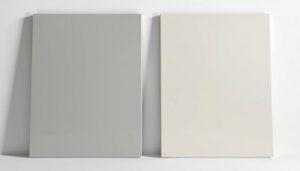

Understanding the different types of torque wrenches available is essential for selecting the best tool for your specific task. You have several options when it comes to torque wrenches, each with its unique features and benefits.

Click-Type Torque Wrenches

Click-type torque wrenches are popular for their ease of use and audible feedback. When the desired torque is reached, they emit a clicking sound, indicating that you can stop applying force.

Beam-Type Torque Wrenches

Beam-type torque wrenches are simple, mechanical tools that display the applied torque on a calibrated beam. They are known for their durability and lack of need for calibration.

Digital Torque Wrenches

Digital torque wrenches use electronic sensors to measure torque and display the value on a digital screen. They offer high precision and additional features like memory storage. Digital torque wrenches beep or light up when the desired torque is reached.

- These wrenches use strain gauge technology to measure applied torque and display the exact value on an LCD screen in real-time.

- Most digital models provide multiple measurement units (N·m, ft-lb, in-lb) that can be switched with the press of a button.

- Advanced features often include programmable torque targets and data storage capabilities.

Understanding Torque Measurements

Understanding the different units of torque measurement is essential for any project requiring precise fastening. Torque is a rotational force that can be measured in various units.

Foot-Pounds (lb·ft)

Foot-pounds (lb·ft) is a unit of torque that represents the force applied at a distance of one foot from the axis of rotation. It’s commonly used in American and British specifications.

Inch-Pounds (lb·in)

Inch-pounds (lb·in) is another imperial unit used for measuring torque, representing the force applied at a distance of one inch from the axis of rotation. It’s often used for smaller fasteners.

Newton-Meters (N·m)

torque measurement, representing the force of one newton applied at a distance of one meter. Many modern torque wrenches feature dual scales, including N·m, to accommodate international specifications. To convert between units, a simple conversion factor is used.

How to Read a Torque-Wrench Scale Correctly

Understanding how to read a torque wrench scale is crucial for achieving accurate torque measurements in your projects. The way you interpret the scale on your wrench can significantly impact the outcome of your work.

Reading a Click-Type Wrench Scale

When using a click-type torque wrench, you’ll need to set the desired torque value and listen for the audible click that indicates the target has been reached. The dial on the wrench should be adjusted to the required setting, and you should be aware of the accuracy of the wrench.

Reading a Beam-Type Wrench Scale

A beam-type wrench displays the torque value on a simple, analog scale. To read it correctly, align your eye with the scale to avoid parallax errors and ensure you’re applying the correct torque. The beam will deflect as you apply force, indicating the value on the scale.

Reading a Digital Wrench Display

Digital torque wrenches provide a clear, numerical display of the torque being applied. These tools often include additional features such as memory storage and programmable alert systems. To get the most out of your digital wrench, familiarize yourself with its settings and ensure the battery level is adequate to maintain accuracy.

Setting the Correct Torque Value

To ensure your project’s integrity, accurately setting the torque value is essential. This process involves several critical steps that help prevent costly mistakes and ensure proper fastener tightening.

Finding the Required Torque Specifications

You need to refer to the manufacturer’s guidelines or technical specifications to find the required torque value for your specific application. This information is usually provided in the product manual or on the manufacturer’s website.

Adjusting the Wrench to the Desired Setting

Once you have the required torque specification, you can adjust your torque wrench accordingly. For example, to set a torque value of 145 lb·ft, you would combine the handle setting (140 lb·ft) with the dial setting (5 lb·ft), as shown in Step 5 of your procedure. After setting, secure the locking knob by turning it clockwise, as described in Step 6.

Verifying Your Settings Before Use

Before using your torque wrench, it’s crucial to verify that the setting is correct. Check both the main scale value and the micrometer collar setting. For click-type wrenches, ensure the locking mechanism is fully engaged. If necessary, test your wrench on a calibration device to confirm its accuracy, especially for critical applications.

By following these steps, you can ensure that your torque wrench is set to the correct torque value, enhancing the quality and reliability of your work.

Step-by-Step Guide to Using a Torque Wrench

Mastering the use of a torque wrench is essential for achieving precise torque. When using a torque wrench, it’s crucial to follow a series of steps to ensure accuracy and prevent damage to your tools or projects.

Preparing the Fastener

Before you start, ensure the fastener is clean and free from debris. Properly seat the socket on the fastener to avoid slippage and incorrect torque application. This step is vital for achieving the desired tightening effect.

Proper Hand Positioning and Technique

Hold the torque wrench with a firm, consistent grip. When tightening, turn the tool at a steady speed, avoiding excessive downforce. This technique helps in achieving the correct torque value.

Recognising When Torque is Reached

Pay attention to the signal that indicates when the desired torque is reached. For click-type wrenches, this is an audible click, while digital wrenches display the value on the screen. Stop applying force once the target torque is achieved.

Common Mistakes to Avoid

Several common mistakes can lead to inaccurate torque application or damage to your tools. These include continuing to apply force after the target torque is reached, using a torque wrench to loosen fasteners, and failing to properly maintain the tool. By avoiding these mistakes, you can ensure the longevity and accuracy of your torque wrench.

Maintaining Your Torque Wrench for Accuracy

Regular maintenance is key to ensuring your torque wrench provides accurate readings. Proper care extends the tool’s lifespan and ensures reliability in your work.

Proper Storage Practices

Store your torque wrench in a dry, clean environment, away from direct sunlight and extreme temperatures. Avoid storing it in a way that could cause bending or damage. Proper storage practices help maintain the wrench’s calibration and overall condition.

Calibration Requirements

To check tool calibration, inspect the pointer when the tool is at rest. If it’s off zero, adjust the pointer shaft until it points to zero. For beam-type wrenches, use a screwdriver to bend the small shaft between the beams closer to the head than the scale.

| Type of Wrench | Calibration Check | Adjustment Method |

|---|---|---|

| Beam-Type | Pointer at rest | Bend pointer shaft |

| Click-Type | Consistent clicking | Professional servicing |

| Digital | Erratic readings | Manufacturer’s guidelines |

Signs Your Wrench Needs Servicing

Be aware of signs indicating your torque wrench needs servicing, such as inconsistent clicking, visual damage, or erratic readings. If your wrench has been dropped, exposed to extreme temperatures, or submerged in liquid, it should be inspected and recalibrated.

Conclusion

The accurate application of torque is vital for the longevity and safety of mechanical components. By mastering how to read a torque wrench scale, you’ll ensure the integrity of your projects. Precise torque application is about understanding specifications and their contribution to component safety.

Regular maintenance and calibration of your wrench will ensure it remains reliable. By following this guide, you’ll confidently use torque to achieve the desired torque and recognise when torque is reached.