Are you aware of the potential risks associated with working with epoxy resin and hardener combinations? When not handled properly, these components can pose serious health hazards and compromise the success of your projects.

To ensure you’re working safely and effectively with epoxy, it’s crucial to understand the fundamental principles of the mixing process. This comprehensive guide will walk you through the essential steps for achieving optimal results with your epoxy projects.

By following the guidelines outlined in this article, you’ll be able to avoid common mistakes and ensure a successful outcome for your DIY or professional projects.

Key Takeaways

- Understand the chemical process involved in mixing epoxy resin and hardener.

- Learn the essential safety protocols for handling epoxy components.

- Discover the importance of proper mixing techniques for achieving optimal results.

- Find out how to prepare for and apply epoxy safely and effectively.

- Gain insights into avoiding common mistakes that can compromise your project’s success.

Understanding Two-Part Epoxy Systems

To work effectively with two-part epoxy, it’s crucial to understand its components and how they interact. You need to grasp the chemistry behind the epoxy system to ensure you’re using it correctly for your projects.

What Is Two-Part Epoxy?

Two-part epoxy consists of a resin (Part A) and a hardener (Part B). When combined in the correct ratio, these components create a chemical reaction that results in a durable, high-strength material. The precise combination of resin and hardener is critical for proper curing and performance.

Different Types of Epoxy Resins and Hardeners

Different types of epoxy resins offer varying properties, from clear casting epoxies to structural adhesives, each designed for specific applications and environments. Similarly, hardeners come in different formulations that affect working time, cure speed, and final properties. Understanding these differences helps you select the right epoxy system for your project.

How Epoxy Curing Works

The curing process of epoxies involves several stages: liquid (open time), gel (initial cure), and solid (final cure), each with distinct characteristics and handling requirements. Factors such as temperature and environment significantly affect the curing process. By understanding these factors, you can achieve optimal results with your epoxy system.

As highlighted by experts, “The key to successful epoxy application lies in understanding the chemistry and the curing process.” Careful measuring and thorough mixing of epoxy resin and resin hardener are essential for the epoxy to cure properly, ensuring a controlled and thorough chemical transition to a high-strength epoxy solid.

Essential Safety Precautions Before Mixing Epoxy

Epoxy safety begins with preparation; understanding the essential safety precautions is vital. When working with epoxy, you are dealing with a material that cures through an exothermic reaction, generating heat in the process.

Personal Protective Equipment (PPE) Requirements

To prevent skin irritation and exposure, it is essential to wear appropriate PPE. This includes gloves that are resistant to chemicals, eye protection such as goggles, and clothing that covers your skin. Choosing the right PPE is crucial for your safety.

Workspace Ventilation Considerations

Proper ventilation is critical to prevent the inhalation of epoxy fumes. Ensure your workspace has adequate air circulation by opening windows or using fans. Good ventilation is key to a safe working environment.

Understanding Exothermic Reactions and Fire Hazards

Epoxy generates heat as it cures, and this heat can become dangerous with larger volumes of material. Be aware that mixing epoxy in certain containers, such as those made of plastic or surrounded by foam, can lead to a significant buildup of heat, potentially causing fires. Understanding the risks associated with exothermic reactions is vital for safe epoxy handling.

Gathering the Right Tools and Materials

Gathering the correct equipment is vital for safely and effectively mixing epoxy for your projects. Having the right tools and materials ensures that you can achieve a high-quality mix, which is crucial for the success of your project.

Measuring Tools: Scales vs. Graduated Containers

Precision is key when mixing epoxy. You can use either digital scales for measuring by weight or graduated containers for measuring by volume. Digital scales offer high accuracy, which is essential for achieving the correct mix ratio.

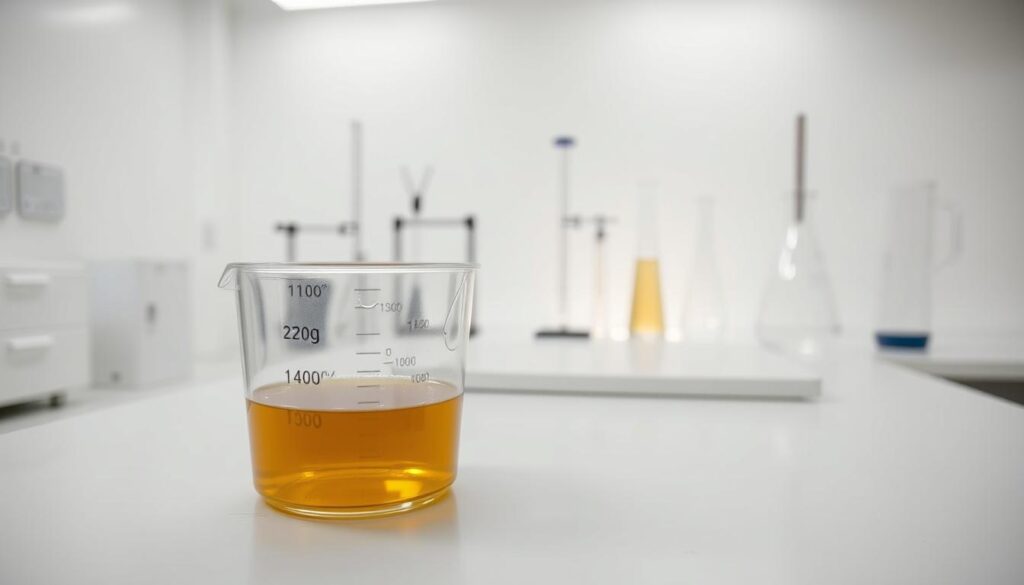

Appropriate Mixing Containers and Sticks

When it comes to mixing epoxy, the type of container you use matters. It’s recommended to use clean plastic, metal, or wax-free paper containers. Avoid using glass or foam containers due to the potential danger from exothermic heat build-up. For mixing, use sturdy sticks or paddles that can withstand the viscosity of the epoxy mixture.

Surface Preparation Materials

Before applying the mixed epoxy, ensure your surface is properly prepared. You’ll need materials like sandpaper for smoothing the surface, cleaning solvents to remove dirt or oil, and applicators for evenly applying the epoxy mixture.

By gathering the right tools and materials, you’ll be well-prepared to tackle your epoxy project with confidence.

How to Mix Two-Part Epoxy Safely: Step-by-Step Process

To achieve a successful epoxy project, it’s crucial to follow a systematic step-by-step process when mixing two-part epoxy. This ensures that the resin and hardener are combined correctly, resulting in a strong and durable finish.

Determining the Correct Mix Ratio

The mix ratio is a critical factor in achieving a successful epoxy application. The ratio of resin to hardener varies depending on the specific product you’re using, so it’s essential to consult the manufacturer’s instructions. For example, a common mix ratio is 2:1 by volume, where you measure out two parts resin to one part hardener.

As noted by an industry expert, “The mix ratio is the foundation of a successful epoxy application. Getting it right is crucial for achieving the desired properties.”

“The mix ratio is critical. If it’s not correct, the epoxy won’t cure properly, leading to a weak or brittle finish.”

Measuring by Weight: Precision Technique

Measuring by weight is a precise method for achieving the correct mix ratio. This involves using a digital scale to measure the exact weight of resin and hardener required. The weight ratio may differ from the volume ratio due to differences in density between the resin and hardener.

| Component | Weight (grams) | Ratio |

|---|---|---|

| Resin | 200 | 2 |

| Hardener | 100 | 1 |

Measuring by Volume: Quick Method

Measuring by volume is a quicker method that can be suitable for certain applications. This involves using graduated containers to measure out the required volumes of resin and hardener. For a 2:1 mix ratio, you would measure out two parts resin to one part hardener by volume.

Proper Mixing Technique and Duration

Once you’ve measured out the resin and hardener, it’s essential to mix them thoroughly. Use a mixing stick to combine the components, scraping the sides, corners, and bottom of the container to ensure a complete mix. Mix for a full 2-3 minutes, or longer for larger quantities.

Tip: Ensure that you mix the components slowly and carefully to avoid introducing air bubbles into the mixture.

Testing for Complete Mixture

To verify that the epoxy is fully mixed, perform a simple test. Take a small amount of the mixed epoxy and apply it to a scrap surface. If it cures evenly and without any soft spots, you can be confident that the mixture is correct.

By following these steps and paying close attention to the mix ratio, measuring technique, and mixing process, you can ensure a successful epoxy application that meets your project’s requirements.

Managing the Curing Process and Troubleshooting

Effective management of the epoxy curing process is crucial for achieving optimal results in your projects. Understanding the factors that influence curing, such as pot life, temperature, and mixing techniques, will help you troubleshoot common issues and ensure a successful outcome.

Understanding Pot Life and Working Time

Pot life refers to the time available to work with the mixed epoxy before it begins to gel. This period varies significantly based on the temperature and quantity of the mixture. To manage pot life effectively, consider using a slower hardener in warmer temperatures or mixing smaller batches to prevent premature curing.

Temperature Effects on Curing

The temperature at which epoxy cures significantly affects its curing time. Warmer temperatures accelerate the curing process, while cooler temperatures slow it down. To adapt to different temperatures, you can adjust your hardener choice or manage the exothermic heat generated by the curing epoxy. For instance, pouring the mixture into a container with a larger surface area, such as a roller pan, can help dissipate heat and extend working time.

| Temperature Condition | Curing Time | Recommended Action |

|---|---|---|

| Warmer Temperatures | Faster Curing | Use slower hardener or mix smaller batches |

| Cooler Temperatures | Slower Curing | Use faster hardener or increase ambient temperature |

Common Mixing Problems and Solutions

Common issues such as incomplete curing, bubbles, or uneven results can be frustrating. For troubleshooting tips, consider visiting our guide on resin troubleshooting. Understanding the causes of these problems and applying the recommended solutions will help you achieve a flawless finish.

By managing the curing process effectively and being aware of potential issues, you can ensure that your epoxy projects turn out as expected. Proper planning and attention to detail during this stage are crucial for a successful outcome.

Conclusion

With the guidelines provided in this article, you’re now equipped to tackle your epoxy projects with confidence and safety. Mixing two-part epoxy requires attention to detail and a thorough understanding of the safety precautions involved.

To achieve the desired properties in your final product, it’s crucial to understand the relationship between resin and hardener. The correct mix ratio is non-negotiable, and using the right measuring tools ensures accuracy. Always read the manufacturer’s instructions for specific guidance on mix ratios and pot life.

Safety should always be your priority when working with epoxy resin. Ensure proper ventilation, use appropriate mixing containers, and be aware of the potential for exothermic heat. By following these guidelines and practicing with small batches, you’ll become proficient in mixing epoxy safely and effectively. This will enable you to achieve professional results in your creative and practical applications.

Remember, different epoxy products have varying requirements, and environmental factors like temperature can significantly impact the curing process. Adjust your approach accordingly to achieve consistent results.