Are you aware that a limescale buildup in your heating system can significantly reduce its efficiency and lifespan? If you’re relying on your combi boiler for hot water and central heating, it’s crucial to maintain its heat exchanger to ensure optimal performance.

Failing to do so can lead to increased energy bills and costly repairs. So, how can you identify if your boiler needs descaling, and what steps can you take to prevent scale buildup?

Key Takeaways

- Understand the importance of maintaining your combi boiler’s heat exchanger for optimal performance.

- Recognise the signs that indicate your boiler needs descaling.

- Learn about DIY descaling methods and professional services available.

- Discover how regular maintenance can save you money on energy bills.

- Prevent costly repairs or premature replacement of your heating system.

Understanding Scale Buildup in Combi Boilers

Combi boilers are prone to scale buildup, particularly in hard water areas. Scale buildup occurs when minerals in the water, such as calcium and magnesium, precipitate out and form limescale deposits on the heat exchanger surfaces.

What Causes Scale in Heat Exchangers

The primary cause of scale buildup in heat exchangers is the presence of hard water. When hard water is heated, the minerals it contains tend to precipitate out and form a hard, adherent layer on the heat exchanger surfaces. This process is exacerbated in combi boilers due to their complex and narrow waterways, which can become easily clogged.

As noted by a user, bad groundwater used to fill a system initially can cause scale problems. For instance, one user mentioned having to reduce the flow rate of city water to household demand hot water due to a partially plugged heat exchanger.

| Cause | Effect |

|---|---|

| Hard water | Scale buildup on heat exchanger surfaces |

| Narrow waterways in combi boilers | Increased susceptibility to scale buildup |

Signs Your Heat Exchanger Needs Descaling

There are several signs that indicate your heat exchanger needs descaling. These include reduced hot water flow, unusual noises from the boiler, and increasing energy bills despite normal usage patterns.

- Reduced hot water flow due to scale buildup restricting water passage.

- Unusual noises from the boiler, such as banging or clunking sounds, caused by scale deposits.

- Increasing energy bills as the boiler works harder to achieve the desired temperature.

If you live in a hard water area, it’s essential to be aware of these signs and take action to descale your boiler’s heat exchanger to prevent further damage.

Why Regular Descaling is Essential

The importance of regular descaling cannot be overstated when it comes to combi boilers. Scale buildup, primarily composed of limescale from hard water, can lead to significant problems if not addressed. Regular descaling maintains your boiler’s efficiency and prolongs its lifespan.

Impact on Boiler Efficiency

Even a small amount of scale buildup can significantly reduce your boiler’s efficiency. This inefficiency can lead to increased energy bills, potentially by up to 25%. Regular descaling ensures that your boiler operates at its optimal level, saving you money on your energy costs.

Preventing Costly Repairs and Breakdowns

Limescale can cause components like pumps, valves, and sensors to fail prematurely. Regular descaling prevents the need for emergency repairs, which are typically more expensive and disruptive than planned maintenance. As noted by experts, “scale in the hydronic side of the system can cause valve failures,” highlighting the importance of descaling.

Extending Your Boiler’s Lifespan

Maintaining a scale-free heat exchanger can extend your boiler’s operational lifespan by several years. This maintenance delays the need to buy a new boiler, saving you a significant upfront cost. Moreover, an efficient heating system reduces carbon emissions, contributing to environmental benefits.

In conclusion, regular descaling is not just a maintenance task; it’s an investment in your boiler’s future performance and longevity. By understanding the impact of scale buildup and taking proactive steps, you can ensure your combi boiler continues to provide efficient heating for your home.

Tools and Materials Needed to Descale Combi Boiler Heat Exchanger

To effectively descale your combi boiler, you’ll need to gather specific equipment and solutions. Descaling is a crucial maintenance task that ensures your boiler operates efficiently and safely.

Descaling Solutions and Chemicals

The type of descaling solution you need depends on the severity of the scale buildup and the manufacturer’s recommendations for your boiler model. You can choose from commercial products specifically designed for boilers or household alternatives like food-grade citric acid or vinegar.

When selecting a descaling solution, consider the material of your heat exchanger and the level of scaling. Some solutions are more aggressive and may be required for severe scaling, while others are gentler and suitable for regular maintenance.

Required Tools and Equipment

A descaling pump is a crucial tool for circulating the descaling solution through your boiler’s heat exchanger. You’ll also need appropriate hoses, connectors, and containers to hold the descaling solution. Some users have found that a small drill-powered pump can be effective, and washing machine hoses can be repurposed for connecting to the boiler.

Safety Equipment

Safety should be your top priority when descaling your combi boiler. You’ll need gloves, eye protection, and appropriate clothing to protect against chemical splashes. Ensure you have a well-ventilated workspace and follow the manufacturer’s instructions for the descaling solution.

Preparing Your Boiler for Descaling

Before you start descaling your combi boiler, it’s crucial to prepare it properly. This involves several key steps to ensure your safety and the effectiveness of the descaling process.

Safety Precautions Before Starting

First and foremost, you must take necessary safety precautions. Turn off the power supply and gas supply to prevent accidents. It’s also a good idea to consult your boiler’s manual for specific instructions on how to do this safely. As one service provider notes, “safety is paramount, and their service contract does not cover costs arising from damage caused by water leaks.”

Isolating the Boiler System

Next, you need to isolate your boiler from the rest of your heating system. This involves closing the appropriate valves and releasing pressure safely. You may need to drain the system partially or fully, depending on the descaling method you plan to use. Ensure you know how to operate the valves and understand the pipe configuration to avoid any complications.

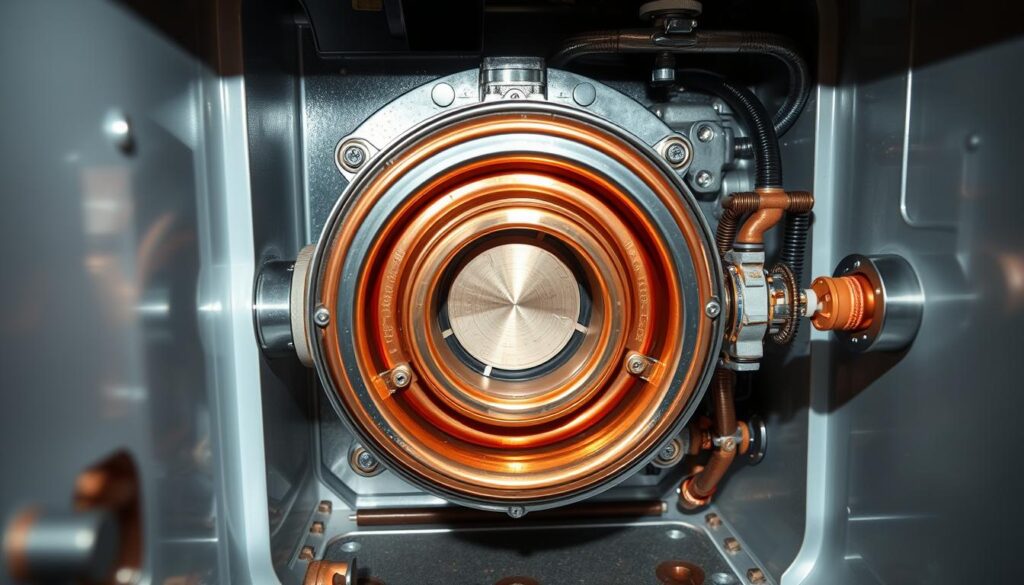

Accessing the Heat Exchanger

Finally, you need to access the heat exchanger. The location and access points can vary depending on the manufacturer and model of your combi boiler. Consult your boiler’s manual to identify the correct procedure for your specific model. It’s essential to follow the manufacturer’s instructions to avoid damaging the heat exchanger or other components.

By following these steps, you can ensure a safe and effective descaling process for your combi boiler.

Step-by-Step Guide to Descale Combi Boiler Heat Exchanger

Maintaining your combi boiler involves descaling the heat exchanger, a task that can be accomplished with the right guidance. Descaling is essential to remove scale buildup that can reduce the efficiency of your boiler and increase your energy bills.

Pump and Bucket Technique

The pump and bucket technique is a common method for descaling a combi boiler heat exchanger. This involves using a pump to circulate a descaling solution through the heat exchanger. To start, you’ll need to connect hoses to the inlet and outlet points of the heat exchanger, typically using washing machine hoses. A small drill-powered pump is then used to circulate the descaling solution.

It’s crucial to mix the descaling solution to the correct concentration to avoid damaging your system. The solution should be circulated for a recommended period, usually between 30 minutes to an hour, depending on the severity of the scale buildup. Monitoring the pH of the solution can help determine when the descaling action is complete.

Using a Descaling Kit

Using a descaling kit is another effective method for descaling your combi boiler heat exchanger. These kits usually come with their own pumps, connectors, and chemicals, making the process more streamlined. The kit’s instructions should be followed carefully to ensure the correct concentration of the descaling solution and the appropriate circulation time.

Descaling kits can simplify the process, as they are specifically designed for this task. However, it’s still important to take necessary safety precautions, such as wearing protective gloves and eyewear.

In-Line Descaling

In-line descaling is a method that allows you to descale your system without disconnecting components, making it a useful technique for regular maintenance. This method involves circulating a descaling solution through the system while it’s still connected. It’s a less invasive method compared to the pump and bucket technique.

| Descaling Method | Complexity | Effectiveness |

|---|---|---|

| Pump and Bucket | Moderate | High |

| Descaling Kit | Low | High |

| In-Line Descaling | Low | Moderate |

Regardless of the method you choose, it’s essential to follow safety guidelines and manufacturer instructions to ensure the job is done correctly and safely.

Flushing and Cleaning After Descaling

Once you’ve descaled your combi boiler, the next critical step is to ensure the system is properly flushed. Flushing is essential to remove any residual descaling solution that could potentially damage your boiler components or affect its efficiency.

Removing All Traces of Descaling Solution

To remove all traces of the descaling solution, you should flush your system multiple times with clean water until the output water is clear. It’s also advisable to test the pH of the water coming out of your system to ensure all acidic descaling solution has been neutralised.

| Flushing Method | Description | Benefits |

|---|---|---|

| Manual Flushing | Involves manually opening the drain valve to let water flow through the system. | Allows for direct control over the flushing process. |

| Using a Hose Pipe | Attaching a hose pipe to the drain valve for more efficient flushing. | Enhances the flushing efficiency by providing a stronger water flow. |

Refilling the System

After flushing, it’s time to refill your heating system. Ensure you use water that is suitable for boiler use and consider adding inhibitors to prevent future scale buildup in the pipes. Once refilled, bleed the radiators to remove any air that may have entered the system during the refilling process, ensuring your heating system operates efficiently and effectively.

Preventative Measures for Scale Buildup

If you live in a hard water area, you’re more likely to experience scale buildup in your combi boiler. Scale buildup can lead to reduced efficiency and increased energy bills.

Water Softeners and Scale Inhibitors

Installing a water softener can significantly reduce scale buildup in your heating system. Water softeners work by removing minerals that cause scale, such as calcium and magnesium, from the water. Alternatively, scale inhibitors can be used to prevent these minerals from depositing on heat exchanger surfaces.

When choosing a water softener or scale inhibitor, consider the size of your household and the level of water hardness in your area. For instance, a salt-based water softener might be more effective for larger households or those with very hard water.

Regular Maintenance Schedule

Establishing a regular maintenance schedule is crucial for preventing scale buildup. This includes annual servicing by a qualified engineer who can inspect your boiler and heating system for signs of scale and perform necessary cleaning or repairs.

In addition to annual servicing, simple daily and monthly habits can help reduce scale buildup. For example, running your hot water at a slightly lower temperature can make a significant difference over time.

When to Call a Professional

While descaling your combi boiler’s heat exchanger can be done DIY, certain situations require the expertise of a heating engineer. Understanding these situations can save you time, money, and ensure your boiler operates safely and efficiently.

Signs That DIY Descaling Isn’t Enough

If you’ve attempted to descale your combi boiler but still experience issues such as reduced water pressure, inconsistent heating, or strange noises, it may be a sign that the problem is more severe than you can handle. Additionally, if you notice signs of leakage or corrosion around the heat exchanger or other components, it’s time to call a professional.

Scale buildup can affect not just the heat exchanger but other parts of your boiler system, leading to more significant problems if not addressed properly. A professional heating engineer can diagnose the issue accurately and perform the necessary repairs or maintenance.

Finding a Qualified Heating Engineer

When looking for a heating engineer to work on your gas boiler system, ensure they are qualified and certified. Look for engineers registered with reputable bodies such as Gas Safe Register in the UK. A reliable heating company will not only fix your current problem but also offer service contracts that include priority attention for breakdowns and annual safety checks.

Establishing a relationship with a trustworthy heating engineer can provide peace of mind and ensure your boiler system is well-maintained. Don’t hesitate to ask potential engineers about their experience with your specific boiler model and scale issues to ensure you’re in good hands.

Conclusion: Maintaining Your Combi Boiler for Optimal Performance

The efficiency and lifespan of your combi boiler depend significantly on proper care. Regular descaling is a crucial aspect of this maintenance, as it prevents scale buildup in the heat exchanger, ensuring your boiler operates effectively.

By investing a little time and money in regular maintenance, you can avoid costly repairs and the need to buy new equipment prematurely. It’s also important to create a personalized maintenance schedule based on your water hardness, boiler usage, and the manufacturer’s recommendations.

Combining DIY maintenance tasks, such as checking for leaks and maintaining proper water pressure, with professional servicing provides the best protection for your heating system. While descaling is an important job, it’s just one part of a comprehensive approach to boiler care.

By following these guidelines and understanding the importance of maintaining your combi boiler, you can enjoy reliable hot water and efficient heat throughout your home, while also prolonging the life of your boiler and its components, including the pipes.