Are you struggling to achieve accurate results in your machining and woodworking projects? Ensuring that your workpiece is securely clamped is crucial for high-quality outcomes and safety in the workshop.

When a workpiece is not clamped firmly, it can lead to vibrations during milling or turning operations, resulting in inaccurate machining and reduced product quality. This comprehensive guide will explore the essential techniques and principles for clamping workpieces correctly, helping you to understand the fundamental principles that ensure workpiece stability.

Key Takeaways

- Understand the importance of proper clamping for achieving accurate results.

- Learn the two golden rules of clamping for securing workpieces safely.

- Discover various clamping methods and tools suitable for different materials and projects.

- Improve your machining and woodworking project quality by selecting the right clamping approach.

- Extend the life of your tools by minimising vibrations during operations.

The Importance of Proper Workpiece Clamping

In machining, the importance of clamping workpieces properly cannot be overstated, as it directly impacts both accuracy and safety. When you clamp a workpiece correctly, you ensure that it remains stable and secure throughout the machining process, which is crucial for achieving precise results.

Why Clamping Matters for Accuracy

Proper clamping is essential for maintaining the accuracy of your machining operations. If a workpiece is not clamped securely, it can shift or vibrate during processing, leading to inaccurate results and potentially damaging your machine or the workpiece itself. By applying the correct clamping pressure, you can prevent such issues and ensure that your workpiece is machined to the required specifications.

As emphasised by industry experts, “The key to precision machining lies in the stability and security of the workpiece during the machining process.” This highlights the significance of using the right clamping techniques and tools to achieve the desired level of precision.

Safety Considerations When Clamping

Safety is another critical aspect of workpiece clamping. Improperly clamped workpieces can become dangerous projectiles if they break free during machining, posing a significant risk to machine operators. To mitigate this risk, it’s essential to follow best practices for clamping, such as:

- Ensuring your workpiece is firmly secured with appropriate clamping pressure before starting any machine.

- Keeping your hands clear of clamping mechanisms when tightening them to avoid injuries.

- Disconnecting the power source before adjusting clamps or repositioning your workpiece.

- Wearing proper personal protective equipment, including safety glasses and gloves, when clamping workpieces.

By prioritising safety and accuracy when clamping workpieces, you can significantly reduce the risk of accidents and improve the overall quality of your machining operations.

Understanding the Fundamentals of Workpiece Clamping

Effective workpiece clamping is the foundation upon which accurate machining results are built. When you clamp a workpiece properly, you ensure that it remains stable and secure during the machining process, thereby achieving the desired precision and quality.

The Two Golden Rules of Clamping

To clamp a workpiece effectively, you need to follow two fundamental principles. Firstly, you must apply sufficient clamping pressure to hold the workpiece firmly in place without causing damage. Secondly, you should ensure that the clamping force is evenly distributed to prevent any distortion or deformation of the workpiece. When dealing with rough or unfinished workpieces, placing a protective material between the vise and the workpiece can prevent marring by the vise jaws.

Common Clamping Mistakes to Avoid

You can avoid several common pitfalls when clamping your workpiece. Some of the most frequent errors include using insufficient clamping pressure, which can lead to workpiece shift during machining, and applying excessive pressure, which can cause distortion, especially in thin or delicate materials. Additionally, failing to protect the surface of your workpiece from damage caused by metal clamp jaws is a common mistake. Positioning clamps where they interfere with the cutting path and neglecting to support overhanging portions of the workpiece are other critical errors to avoid.

By understanding and adhering to these principles, you can significantly improve the accuracy and quality of your work, ensuring that your workpiece is properly clamped for successful machining.

The 3-2-1 Principle: A Clamp Workpieces Properly Guide

When it comes to clamping workpieces, the3-2-1 principle is a fundamental guideline that ensures accuracy and stability. This principle is widely used in machining and manufacturing to secure workpieces properly, preventing movement during processing.

Explaining the3-2-1 Positioning Method

The3-2-1 positioning method involves using a specific arrangement of fixture points to constrain the workpiece. This method dictates that the workpiece should be supported by three points in the primary plane, two in the secondary plane, and one in the tertiary plane. This arrangement ensures that the workpiece is fully constrained, preventing any unwanted movement.

By following the3-2-1 principle, you can ensure that your workpiece is properly clamped, reducing the risk of errors during machining. This method is particularly useful for complex parts, where precise positioning is critical.

Avoiding Under and Overdetermined Clamping

Deviating from the3-2-1 principle can result in either underdetermined or overdetermined clamping. Underdetermined clamping occurs when fewer than six locating points are used, leaving the workpiece with too many degrees of freedom. Conversely, overdetermined clamping happens when more than six locating points are used, potentially creating conflicting constraints that can distort the workpiece.

| Clamping Type | Description | Consequences |

|---|---|---|

| Underdetermined Clamping | Fewer than 6 locating points | Workpiece vibration, shifting during cutting |

| Overdetermined Clamping | More than 6 locating points | Distortion, internal stresses affecting accuracy |

To avoid these issues, it’s essential to strike a balance between adequate support and avoiding overdetermination, particularly when working with thin or flexible materials.

Essential Clamping Tools and Equipment

Proper clamping starts with the right tools and equipment. Having the correct clamps for the job ensures that your workpieces are held securely, allowing for accurate and precise work.

Basic Clamps Every Workshop Needs

For most clamping tasks, a set of basic clamps will suffice. C-clamps, for instance, are versatile and effective for applying pressure. Their long threaded rod provides a large capacity, making them ideal for various applications, including frame-making.

C-clamps are particularly useful due to their ability to align perpendicular pieces as you apply clamping pressure. For tasks that require precision and a firm grip, these clamps are indispensable.

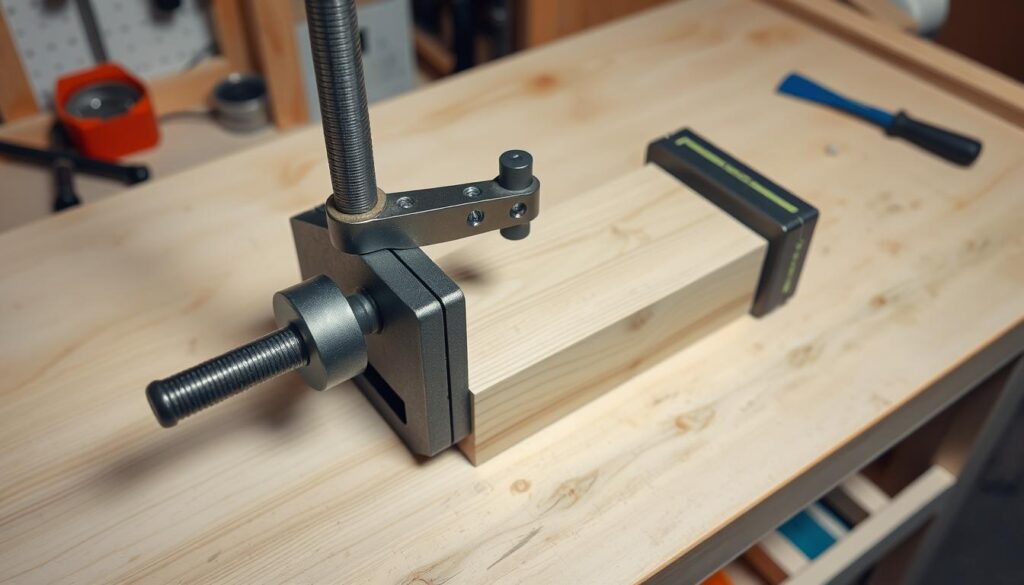

Specialised Clamping Tools for Specific Applications

Beyond basic clamps, there are specialised tools designed for specific tasks. For example, corner clamps are invaluable for holding workpieces at precise 90-degree angles, making them perfect for frame assembly and cabinet making.

Other specialised clamps include band clamps, edge clamps, magnetic clamps, and vacuum clamping systems. Each of these serves a unique purpose, such as clamping polygonal shapes or securing ferrous metal workpieces.

| Clamp Type | Application | Key Feature |

|---|---|---|

| Corner Clamps | Frame assembly, cabinet making | Precise 90-degree angle holding |

| Band Clamps | Polygonal shapes, mitered frames | Even pressure distribution |

| Edge Clamps | Edge-banding operations | Special jaws for even pressure |

| Magnetic Clamps | Metalworking applications | Quick securing of ferrous metals |

Five Primary Clamping Techniques

Effective clamping techniques are critical for maintaining precision and control during machining processes. The choice of clamping technique depends on the type of workpiece, its material, and the specific machining operation. Here, we will explore five primary clamping techniques used in various industries.

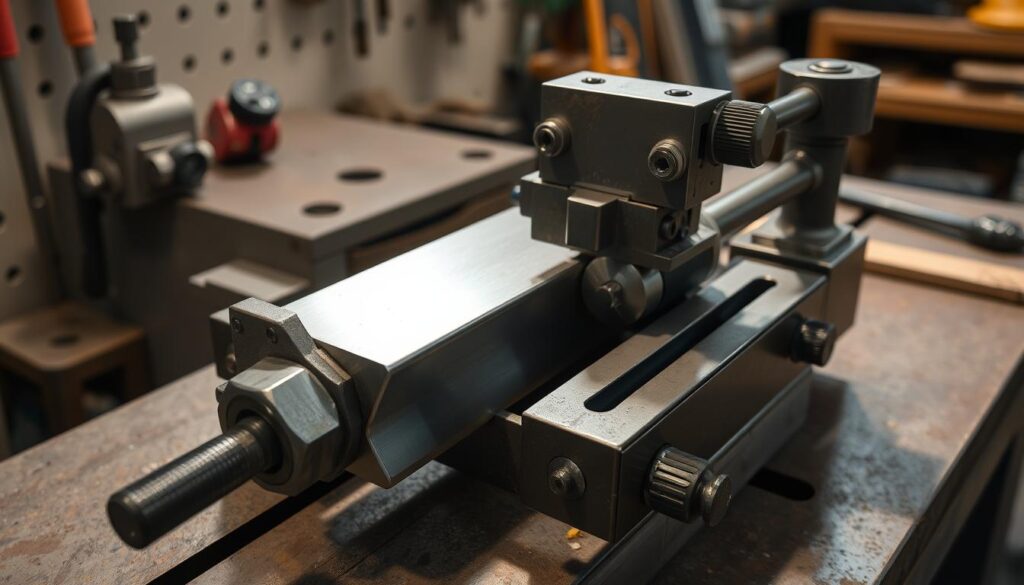

Mechanical Clamping Methods

Mechanical clamping methods involve using physical devices such as clamps, vises, and fixtures to hold the workpiece in place. These methods are versatile and can be used for a wide range of materials and shapes. Mechanical clamping is particularly useful when working with complex geometries or when high clamping forces are required. You can find more information on mechanical clamping methods on the Unisign website.

Hydraulic Clamping Systems

Hydraulic clamping systems use hydraulic pressure to apply clamping forces, offering high precision and control. These systems are ideal for heavy-duty machining operations where high clamping forces are necessary. Hydraulic clamping systems provide consistent clamping pressure, reducing the risk of workpiece distortion or damage.

Pneumatic Clamping Applications

Pneumatic clamping applications utilize compressed air to generate clamping forces, making them suitable for high-speed machining operations. Pneumatic clamping systems are often used in applications where rapid clamping and unclamping are necessary, such as in automotive manufacturing.

Magnetic Clamping Solutions

Magnetic clamping solutions employ magnetic forces to hold ferromagnetic workpieces in place. These solutions are particularly useful for machining thin or delicate parts, as they provide a secure hold without applying excessive pressure. Magnetic clamping is commonly used in grinding and milling operations.

Vacuum Clamping Technology

Vacuum clamping technology uses negative pressure to hold workpieces firmly against a flat surface, making it ideal for materials that cannot be held with magnetic systems, such as aluminium, plastics, and composites. This technique is particularly valuable for machining thin, flat materials that might warp or distort under conventional clamping methods. Modern vacuum clamping systems feature zoned tables that allow you to activate only the areas needed for your specific workpiece shape, maximizing efficiency and holding power.

When using vacuum clamping, ensure that there is enough surface area to create the necessary clamping force. The effectiveness of vacuum clamping depends on having a sufficient contact area and an airtight seal. Porous materials may require sealing or the use of sacrificial backing boards to achieve proper holding force.

Clamping Methods for Different Workpiece Types

Different workpiece types require tailored clamping methods to ensure precision and safety. The effectiveness of the clamping technique directly influences the accuracy and quality of the machining operation.

Clamping Flat and Rectangular Workpieces

When clamping flat and rectangular workpieces, it’s essential to distribute the clamping force evenly. Use clamps on both sides of the workpiece to increase the bearing surface area, thus enhancing the clamping force. The clamps should be secured using T-slot bolts inserted into the T-slots milled into the table. Ensure that the clamp supports are at the same height as the workpiece to prevent springing during cutting.

Securing Cylindrical and Irregular Shapes

Cylindrical and irregularly shaped workpieces require specialized clamping techniques. For cylindrical workpieces, consider using V-blocks or clamps specifically designed for cylindrical shapes. For irregular shapes, custom-made clamping fixtures or adjustable clamps can provide the necessary support and holding force.

Clamping Thin Materials Without Distortion

Clamping thin materials demands careful consideration to prevent distortion. Use clamps with broad, flat surfaces to distribute the clamping force evenly. Additionally, consider using vacuum clamping or magnetic clamping for thin materials, as these methods can provide uniform support without causing deformation.

Working with Oversized or Heavy Workpieces

Oversized or heavy workpieces necessitate special clamping arrangements. Use multiple clamps in concert to provide adequate holding force. For workpieces that extend beyond the machine table, employ additional support stands or table extensions to prevent sagging. Toe clamps in conjunction with T-slot bolts can offer maximum holding power against cutting forces.

| Workpiece Type | Recommended Clamping Method | Key Considerations |

|---|---|---|

| Flat and Rectangular | Clamps on both sides, T-slot bolts | Clamp supports at same height as workpiece |

| Cylindrical and Irregular | V-blocks, custom fixtures, adjustable clamps | Ensure even support, prevent movement |

| Thin Materials | Vacuum clamping, magnetic clamping | Prevent distortion, uniform support |

| Oversized or Heavy | Multiple clamps, toe clamps, T-slot bolts | Adequate holding force, prevent sagging |

Advanced Clamping Strategies for Precision Work

To ensure precise results, you need to adopt sophisticated clamping methods. Advanced clamping strategies are vital for precision work, enabling you to achieve accurate and consistent results in your machining operations.

Using Fixtures for Repetitive Tasks

Fixtures are custom-made devices designed to hold specific workpieces in place, allowing for repetitive tasks to be performed with high precision. By using fixtures, you can significantly reduce setup time and increase productivity in your workshop.

Angle Plates and Compound Positioning

Angle plates provide a versatile clamping solution for complex workpieces, enabling you to position and secure the workpiece at precise angles. Compound positioning involves using multiple angle plates or fixtures to achieve the desired orientation, which is particularly useful for intricate machining operations.

Clamping Between Centres for Cylindrical Work

Clamping between centres is a specialized technique for cylindrical workpieces, providing excellent concentricity and allowing for rotation during machining. This method requires precise alignment of the headstock and tailstock centres to prevent runout.

| Clamping Method | Workpiece Type | Advantages |

|---|---|---|

| Fixtures | Specific, repetitive tasks | Reduced setup time, increased productivity |

| Angle Plates | Complex, angular workpieces | Precise positioning, versatile clamping |

| Between Centres | Cylindrical workpieces | Excellent concentricity, rotation during machining |

When working with cylindrical pieces, using hardened steel centres and properly prepared centre holes is essential. For longer pieces, consider using a steady rest to prevent deflection under cutting forces.

Conclusion: Mastering the Art of Proper Workpiece Clamping

The ability to clamp workpieces effectively is fundamental to achieving precise results in various machining operations. Throughout this guide, we’ve explored various clamping tools and techniques, providing you with a comprehensive understanding of how to secure workpieces of different shapes and sizes.

By applying the 3-2-1 principle and adhering to the two golden rules of clamping, you’ll ensure that your workpieces are properly positioned and secured. Different materials, such as steel and wood, require specific approaches to prevent damage and distortion.

As you continue to develop your skills, experimenting with different clamping options will help you select the optimal method for any project. By investing time in setting up proper clamping, you’ll achieve professional results, protect your tools, and ensure safe workshop operations.