Are you struggling to determine the right drill bit for your project?

Selecting the correct drill bit is crucial for achieving clean, precise holes and preventing damage to your tools and materials. With various drill bits available, understanding how to match them to specific materials is essential for optimal results.

This comprehensive guide will explore the anatomy of drill bits, explain how different bits work, and provide detailed information on which bits to use for various materials, ensuring efficient drilling and professional-looking results.

Key Takeaways

- Understand the various types of drill bits and their applications.

- Learn how to match drill bits to specific materials for optimal results.

- Discover the importance of selecting the right drill bit for your project.

- Improve the quality of your work by using the appropriate drill bit.

- Enhance your drilling efficiency and achieve professional-looking results.

Understanding Drill Bit Basics

Understanding the basics of drill bits is essential for achieving successful drilling outcomes across different materials and applications. You need to be aware of the design variations and functionalities that make a drill bit suitable for specific tasks.

Anatomy of a Drill Bit

The anatomy of a drill bit is crucial in determining its effectiveness. The part that differs between drill bit types is usually the cutting lip. Different designs make some bits more suited to cutting through certain materials than others. The design also varies depending on the power drill they need to fit and the type of hole being drilled.

How Drill Bits Work

Drill bits work by combining rotational force with downward pressure to cut through materials and create holes of specific diameters. The cutting action varies depending on the bit design, with some bits scraping material away while others chip or grind through harder substances. Key factors influencing the effectiveness include:

- The drilling speed and pressure applied.

- The material’s properties, such as hardness and density.

- The bit’s ability to manage heat generation, particularly in dense materials.

- Proper technique, including occasional withdrawal to clear debris.

By matching the drill bit design to the material’s properties and employing the right drilling technique, you can maximise the efficiency and lifespan of your drill bits.

Choosing Correct Drill Bits for Material

To ensure successful drilling, it’s essential to match the drill bit to the material. Using the right drill bit can significantly impact the quality of the result, whether you’re working with wood, metal, or masonry.

Why Material Matching Matters

Matching the drill bit to the material is crucial because different materials have unique properties that require specific drill bit characteristics. For instance, drilling into metal requires a drill bit designed for metal, as masonry bits are not suitable for this task. Using the correct bit helps prevent damage to both the material and the drill bit itself.

Common Mistakes to Avoid

When drilling, several common mistakes can be avoided by taking the right precautions. These include using the wrong type of drill bit for the material, neglecting to adjust speed settings, failing to use pilot holes, applying too much pressure, and overlooking safety precautions.

- Using masonry bits for metal or metal bits for wood can damage both the material and the bit.

- Neglecting to adjust speed settings can lead to overheating or material damage.

- Failing to use pilot holes can result in splintering or excessive strain on the drill.

- Applying too much pressure can bend or break the drill bit.

- Overlooking safety precautions can lead to injuries from flying debris or dust.

Drill Bit Materials and Coatings

The right combination of materials and coatings can greatly enhance the efficiency and longevity of your drill bits. When it comes to drill bits, the material used and its coating play a crucial role in determining its performance and lifespan.

High-Speed Steel (HSS)

High-Speed Steel (HSS) drill bits are a popular choice due to their durability and ability to withstand high temperatures. HSS bits are suitable for drilling into various materials, including metal, wood, and plastic. They offer a good balance between hardness and toughness, making them versatile for general-purpose drilling tasks.

Cobalt and Carbide Options

For more demanding applications, cobalt and carbide drill bits are preferred. Cobalt bits are known for their enhanced hardness and resistance to wear, making them ideal for drilling into tough materials like stainless steel. Carbide bits, on the other hand, are extremely hard and are used for drilling into very hard materials, such as masonry and concrete.

Coatings and Their Benefits

Drill bit coatings significantly enhance performance by reducing friction, increasing hardness, and improving heat resistance. Common coatings include Black Oxide, Titanium Nitride (TiN), and Titanium Aluminium Nitride (TiAlN). These coatings not only extend the life of drill bits but also improve their drilling efficiency, especially when working with challenging materials.

Wood Drilling Bits

When working with wood, selecting the right drill bit is crucial for achieving precise and clean holes. The type of drill bit used can significantly impact the quality of the finished product.

Twist Bits for General Wood Work

Twist bits are a versatile option for general wood work, suitable for drilling small to medium-sized holes. They are available in various sizes and are ideal for pilot holes or screwing into wood.

Brad Point and Auger Bits

Brad point bits are designed for precision drilling, featuring a sharp point that helps to avoid splintering the wood. Auger bits, on the other hand, are used for drilling larger holes and are often employed in woodworking and construction projects.

Spade and Forstner Bits for Larger Holes

Spade bits, also known as paddle bits, are used for quickly drilling large diameter holes in wood. Forstner bits are specialist drill bits that create large, flat-bottomed holes, ideal for tasks such as fitting hinges.

Forstner bits excel at drilling clean, flat-bottomed holes with smooth sides, making them the preferred choice for high-quality cabinetry, furniture making, and door hardware installation.

Metal Drilling Bits

When drilling into metal, selecting the right drill bit is crucial for achieving precise and clean holes. The type of metal you’re working with will determine the best drill bits to use.

HSS Bits for Soft Metals

For soft metals like aluminium or copper, High-Speed Steel (HSS) bits are often the best choice. These bits are designed to withstand high drilling speeds and are suitable for general-purpose drilling applications.

Cobalt Bits for Stainless Steel

When working with harder metals like stainless steel, cobalt drill bits are recommended. Cobalt bits are made from a high-strength alloy that resists wear and maintains its hardness even at high temperatures, making them ideal for drilling into tough metals.

Step Bits for Sheet Metal

Step drill bits are specifically designed for drilling into sheet metal. These bits feature a unique cone-shaped design with multiple diameter steps, allowing a single bit to drill holes of various sizes in thin materials without changing bits.

The benefits of step bits include creating clean holes without deformation, burrs, or tearing, and automatically deburring holes as they’re drilled. This makes them particularly valuable for applications like ductwork, electrical panels, and other sheet metal work.

Masonry and Concrete Bits

Masonry and concrete drilling requires specialised drill bits designed to withstand the rigors of hard, abrasive materials. When working with masonry or concrete, the right drill bit can make all the difference in achieving professional results.

Tungsten Carbide-Tipped Bits

Tungsten carbide-tipped bits are a popular choice for masonry drilling due to their durability and effectiveness. These bits feature a tungsten carbide tip that provides excellent hardness and resistance to wear, making them ideal for drilling into hard materials.

SDS Bits for Heavy-Duty Work

SDS bits are designed for heavy-duty masonry work and are known for their ability to withstand high torque and drilling forces. These bits have a unique shank design that allows for efficient energy transfer, making them suitable for demanding applications.

Diamond-Tipped Options

Diamond-tipped drill bits represent the premium option for drilling extremely hard materials like porcelain tile, granite, and reinforced concrete. Featuring industrial diamonds embedded in the cutting surface, these bits offer superior hardness and abrasion resistance, making them a valuable tool for professionals and serious DIYers.

Specialised Drill Bits

When tackling diverse DIY projects, having the right specialised drill bits can make all the difference. Specialised drill bits are designed to handle specific materials and tasks, enhancing the of your DIY projects.

Tile and Glass Bits

For drilling through tile and glass, specialised bits are available that prevent cracking and ensure clean holes. These bits typically have a spear-point or diamond-coated tip.

Countersink and Plug Cutter Bits

Countersink bits allow for the creation of conical holes for screw heads, while plug cutters enable the making of wooden plugs to cover these screws, providing a flush finish.

These bits are particularly useful for woodworking projects where a smooth surface finish is desired.

Multi-Material Bits

Multi-material drill bits are versatile tools designed to drill effectively through various materials, including wood, metal, plastic, tile, and masonry. They feature carbide tips with specially designed cutting edges and unique flute patterns.

These bits are ideal for DIY enthusiasts who require versatility without needing multiple specialised bit sets.

In summary, specialised drill bits such as tile and glass bits, countersink and plug cutter bits, and multi-material bits offer solutions for a wide range of DIY tasks, enhancing precision and efficiency.

Understanding Drill Bit Shanks and Angles

The geometry of a drill bit, including its shank and angle, is critical for its overall performance. When selecting a drill bit, it’s essential to consider the type of material you’ll be working with and the specific requirements of your project.

Shank Types Explained

The shank of a drill bit is the part that is held in the drill chuck. Different shank types are designed for specific applications, such as straight shanks for general-purpose drilling and hexagonal shanks for improved torque and reduced slippage.

Point Angles for Different Materials

The point angle of a drill bit significantly affects its performance in various materials. For example, a drill bit with a 118° angle is suitable for soft materials like wood, while a 135° angle is better suited for harder materials like masonry. When working with metal, the point angle can range from 90° to 145°, depending on the specific type of metal and the drill bit material.

Different types of drill bits are designed for specific drilling applications, and understanding the various point angles and shank types is crucial for achieving optimal results. By selecting the right drill bit for your project, you can ensure efficient and accurate drilling and achieve professional-grade outcomes.

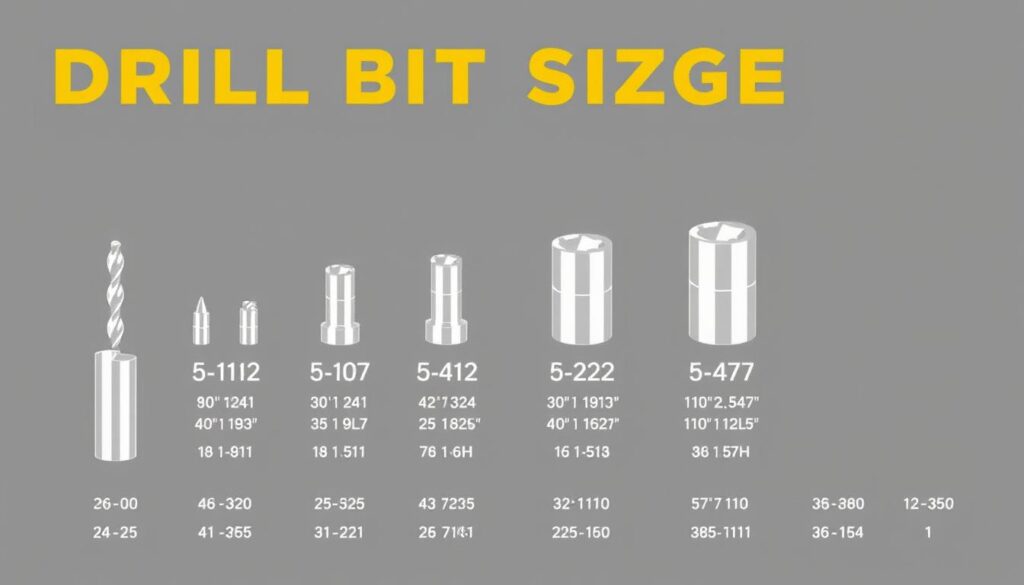

Drill Bit Size Guide

Understanding the correct drill bit size is essential for your project’s success, whether you’re hanging a picture or installing heavy fixtures. Using the right drill bits ensures that your wall plugs or anchor bolts fit perfectly, providing a secure hold.

Wall Plug Sizing

When using wall plugs, it’s crucial to match the drill bit to the plug size. For instance, an M10 anchor bolt requires a 16mm drill bit, while an M8 bolt needs a 14mm bit. Always consult the manufacturer’s guidelines for specific drill bit recommendations to ensure a snug fit.

Bolt and Screw Sizing

For screws, the pilot hole should match the screw’s minor diameter. In softwoods, a pilot hole about 70% of the screw’s major diameter is ideal, while in hardwoods, it’s closer to 90%. For machine bolts, clearance holes should be slightly larger than the bolt’s diameter. For example, an M8 bolt requires a 9mm clearance hole. Following these guidelines ensures that your bits used are appropriate for the task, providing optimal holding power without damaging the material.

Conclusion

In conclusion, the key to efficient drilling lies in understanding the different types of drill bits and their applications. By selecting the right drill bit for your specific material, you can achieve professional results and extend the life of both your bits and your drill.

Understanding the various drill bits available, from standard twist bits to specialised options for wood, metal, and masonry, empowers you to make informed choices. The material composition of drill bits, whether high-speed steel, cobalt, or carbide, significantly impacts their performance.

By investing in quality bits designed for your specific needs and maintaining them properly, you’ll enjoy more efficient and satisfying drilling experiences.