Did you know that a well-stocked tool kit can save UK homeowners a significant amount of money on maintenance and repair costs? Having the right tools at your disposal enables you to tackle minor household tasks efficiently, reducing the need for professional interventions.

As a homeowner in the UK, you’re likely to encounter various tasks that require immediate attention, from fixing leaky faucets to tightening loose fixtures. By understanding the basics of home maintenance, you can prevent minor issues from escalating into major problems.

Key Takeaways

- Understand the importance of having the right tools for home maintenance.

- Learn how to select the appropriate tools for various household tasks.

- Discover how to build your tool collection strategically over time.

- Gain insights into tool quality considerations for effective repair work.

- Find out how proper tool usage can save time and frustration.

Why Every UK Homeowner Needs a Basic Tool Kit

A basic tool kit is a must-have for every UK homeowner, enabling them to perform routine maintenance and repairs. Having the right tools at your disposal can make a significant difference in how you manage your home. It’s not just about having a collection of tools; it’s about having the right tool for the job.

Investing in a good tool kit can save you money in the long run by allowing you to tackle minor repairs and maintenance tasks yourself. This is particularly beneficial for UK homeowners who want to be more self-sufficient and less reliant on professional services for every small issue.

The Cost-Saving Benefits of DIY Home Repairs

DIY home repairs can significantly reduce your maintenance costs. By having a basic tool kit, you can address common household issues without having to call a professional. This not only saves you money on service fees but also gives you a sense of accomplishment and independence.

Moreover, being able to perform simple repairs and maintenance tasks can prevent minor issues from becoming major problems, further reducing your overall expenditure on home maintenance.

Understanding Tool Quality and Investment Value

When it comes to buying tools, the general rule is to invest in good quality. High-quality tools are not only more durable and long-lasting, but they also enhance safety by reducing the risk of accidents caused by faulty or breaking tools. You can identify a quality tool by its smooth machining, well-balanced design, and comfortable grip.

While it might be tempting to opt for cheaper tools, the long-term benefits of investing in quality far outweigh the initial cost savings. A good tool can last a lifetime with proper care, making it a valuable addition to your home maintenance arsenal.

In conclusion, having a basic tool kit is indispensable for UK homeowners. It empowers you to handle home repairs and maintenance tasks efficiently, saving you money and enhancing your sense of self-sufficiency. By understanding the importance of tool quality and safety, you can make informed decisions when it comes to building and maintaining your tool kit.

Essential Measuring Tools for Precise Home Repairs

To tackle home repairs with confidence, it’s essential to have the right measuring tools at your disposal. Accurate measurements are vital for ensuring that your DIY projects are completed successfully and safely.

Learn More

Tape Measures and Rulers: Getting Accurate Measurements

A good quality tape measure is indispensable for any homeowner. It allows you to measure rooms, objects, and materials accurately. When choosing a tape measure, consider one that is durable and has both metric and imperial measurements.

Rulers, on the other hand, are perfect for measuring smaller objects or for tasks that require more precision. A combination square can also be useful for ensuring accurate 90-degree angles.

Levels and Squares: Ensuring Everything Is Straight

A spirit level ensures that surfaces are perfectly horizontal or vertical, which is crucial for hanging pictures, installing shelves, or laying tiles. There are various types of levels, including bubble levels and laser levels, each with its own set of advantages.

A combination square or try square is another essential tool for verifying that corners are square and that edges are straight.

Stud Finders and Chalk Lines: Locating Wall Supports

When hanging heavy items or performing more complex repairs, locating the wall studs is essential. A stud finder is a handy tool that detects the wooden studs behind your walls. There are magnetic, electronic, and advanced models available in the UK market.

A chalk line is used for marking straight lines over long distances, such as when replacing wallpaper or laying flooring tiles. It’s a simple yet effective tool for ensuring alignment.

Must-Have Repair Tools for Fastening and Securing

Learn More

To ensure your home repairs are done correctly, you’ll need the right tools for fastening and securing. This includes a variety of fastening tools that can handle different materials and tasks.

Hammer Selection: Types and Uses in Home Repairs

A good hammer is a fundamental tool in any home repair kit. There are several types of hammers, each designed for specific tasks. For instance, a claw hammer is versatile and can be used for both driving nails and pulling them out. A ball-peen hammer, on the other hand, is ideal for shaping metal and closing rivets.

Screwdrivers: Standard, Phillips, and Speciality Types

Screwdrivers are another essential tool for fastening and securing. You’ll need a set that includes standard (flathead), Phillips, and possibly speciality types like Torx or hex (Allen) drivers. Having the right screwdriver ensures that you can drive screws efficiently without damaging them or the surrounding material.

Wall Anchors and Fasteners for Different Materials

When hanging items on your wall, it’s crucial to use the appropriate wall anchors to ensure they can support the weight. For plasterboard or drywall, plastic or metal E-Z Ancor bolts are effective. For heavier items or for use in masonry, toggle bolts provide extra strength. Understanding the type of wall you’re dealing with and choosing the right fastener is key to a successful repair.

- We’ll explore the various wall anchors and fasteners available for UK wall types, including plasterboard/drywall, masonry, and lath and plaster.

- You’ll learn how to match the appropriate anchor type to the weight of the item being hung and the wall material.

- The subsection will explain weight ratings for different anchors and how to calculate the required support for shelving and wall-mounted items.

- We’ll discuss specialised anchors for hollow doors, ceiling mounting, and other challenging surfaces.

- The discussion will include tools needed for proper anchor installation and common installation mistakes to avoid.

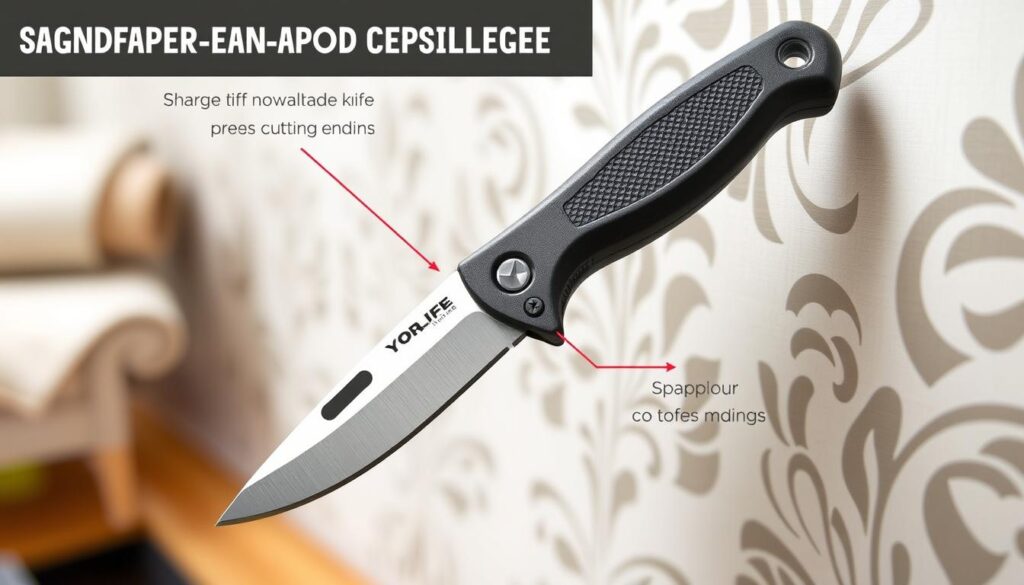

Cutting Tools Every UK Home Should Have

Learn More

Cutting tools are a fundamental component of any homeowner’s toolkit in the UK, enabling them to undertake repairs and renovations. Having the right cutting tools can make a significant difference in the quality and efficiency of DIY projects.

Handsaws: Crosscut, Ripsaw, and Speciality Saws

Handsaws are a crucial part of any toolkit, providing a manual means of cutting various materials. A crosscut saw is used for cutting across the grain of wood, while a ripsaw is designed for cutting along the grain. Speciality saws, such as dovetail and tenon saws, are used for more precise joinery tasks.

Utility Knives and Scissors: Precision Cutting Tools

Utility knives and scissors are versatile cutting tools used for a variety of tasks, from cutting drywall to trimming carpet. Utility knives are particularly useful for making precise cuts in various materials, while scissors are ideal for cutting softer materials like fabric and plastic.

Power Saws: When to Invest in Electric Cutting Tools

Power saws are a significant investment for any homeowner, offering increased efficiency and precision when cutting various materials. When choosing a power saw, consider the type of projects you will be undertaking and the materials you will be working with. Circular saws, jigsaws, and reciprocating saws are popular options, each with its own unique benefits and applications.

For instance, a circular saw is ideal for making straight cuts in wood and other materials, while a jigsaw is better suited for curved cuts. Always follow safety guidelines when operating power saws, including wearing protective eyewear and maintaining a firm grip on the saw.

When using power saws, it’s essential to select the correct blade for the material being cut. Different blades are designed for cutting wood, metal, or plastic, and using the wrong blade can result in poor cut quality or damage to the saw. Additionally, consider the power source of your saw, whether it’s corded or cordless, and choose a model that suits your needs.

Essential Pliers and Wrenches for Home Repairs

Learn More

A well-equipped homeowner’s toolkit should include a variety of pliers and wrenches to tackle different repair jobs effectively. These tools are essential for gripping, twisting, and bending various objects, making them indispensable for home repairs.

Types of Pliers: Slip-Joint, Needle-Nose, and Locking

Pliers come in several types, each designed for specific tasks. Slip-joint pliers are versatile and can be used for gripping objects of various sizes. Needle-nose pliers are ideal for reaching into tight spaces and gripping small objects. Locking pliers can be locked in place, allowing for secure grip on objects.

Wrench Selection: Adjustable, Combination, and Socket Sets

Wrenches are crucial for turning bolts and nuts. An adjustable wrench can be used on various sizes of fasteners, making it a versatile tool. A combination wrench offers both an open-end and a box-end, providing flexibility. Socket sets are comprehensive and can be used for a wide range of tasks, from simple repairs to complex projects.

Speciality Gripping Tools for Specific Tasks

For specific tasks, specialised gripping tools are necessary. Pipe wrenches are used for gripping pipes, while strap wrenches are ideal for delicate surfaces. Basin wrenches are used for tightening or loosening faucet mounting nuts in tight spaces.

By including these essential pliers and wrenches in your toolkit, you’ll be well-prepared to tackle various home repair tasks efficiently.

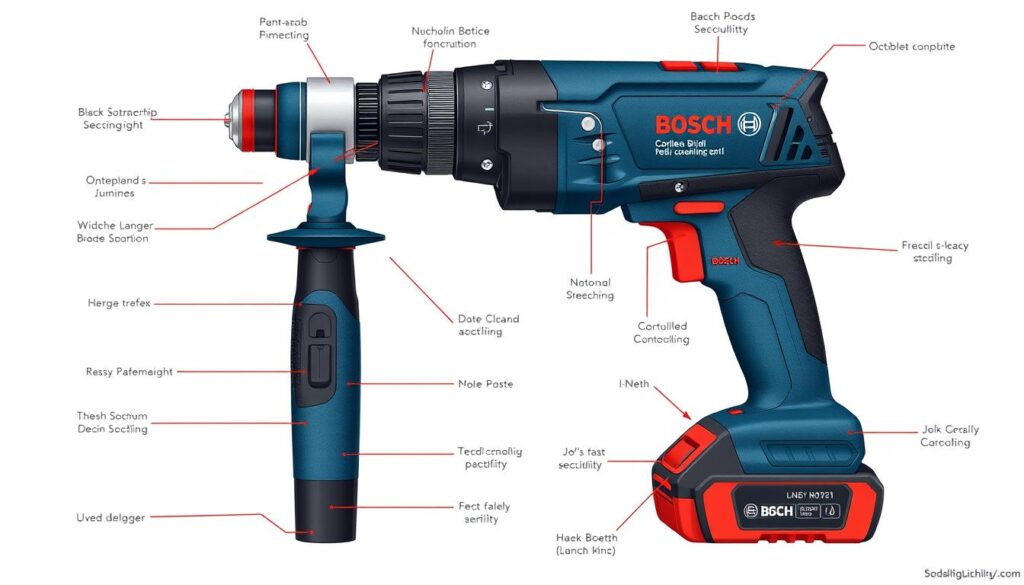

Drilling Equipment for UK Home Improvement Projects

Learn More

UK homeowners undertaking improvement projects need to be equipped with the appropriate drilling tools. Drilling equipment is a fundamental component of any home improvement task, allowing you to complete a variety of projects efficiently.

Power Drills: Corded vs. Cordless Options

When selecting a power drill, you have two primary options: corded or cordless. Corded drills provide consistent power and are ideal for heavy-duty tasks, while cordless drills offer greater flexibility and convenience. Your choice depends on the specific requirements of your projects and personal preference.

Essential Drill Bits for Different Materials

The type of drill bit you need depends on the material you’re working with. For instance, twist drill bits are versatile and suitable for drilling into wood and metal, whereas spade bits are better for making larger holes in wood. Understanding the different types of drill bits and their applications is crucial for achieving professional results.

| Drill Bit |

Drill Type |

Use |

| Twist |

Hand, power, or drill press |

Small-diameter holes in wood and metal |

| Spade |

Power or drill press |

Holes up to 1 1/2 inches in wood |

| Auger |

Braces |

Holes up to 1 1/2 inches in wood |

| Expansion |

Brace |

Holes up to 3 inches in wood |

| Fly cutter |

Drill press |

Holes up to 6 inches in wood; smaller holes in other materials |

| Hole saw |

Power or drill press |

Holes up to 3 inches in wood |

Drill Accessories and Attachments

To enhance the functionality of your drill, consider investing in various accessories and attachments. These include depth stops, dust collection attachments, and drill guides, which improve accuracy and cleanliness. Additionally, versatile attachments can transform your drill into other tools, such as sanders, mixers, and screwdrivers, making it a valuable addition to your tool set for various tasks.

You’ll also find bit extension accessories useful for reaching difficult areas and right-angle attachments for tight spaces. Furthermore, chuck adapters allow for using different bit shank types with your drill, expanding its capabilities. Proper storage solutions for organising drill bits and accessories are also essential to prevent loss and damage.

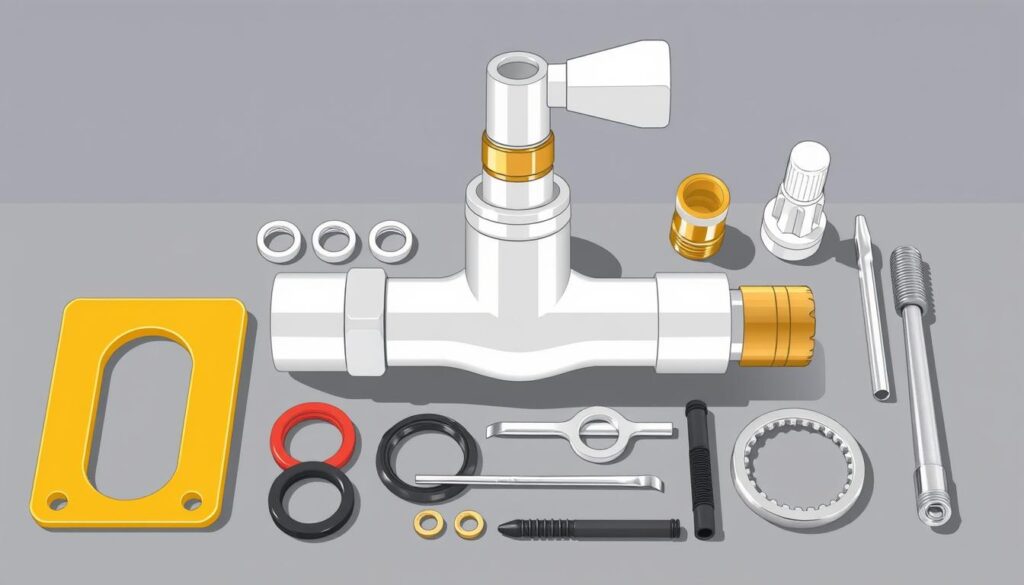

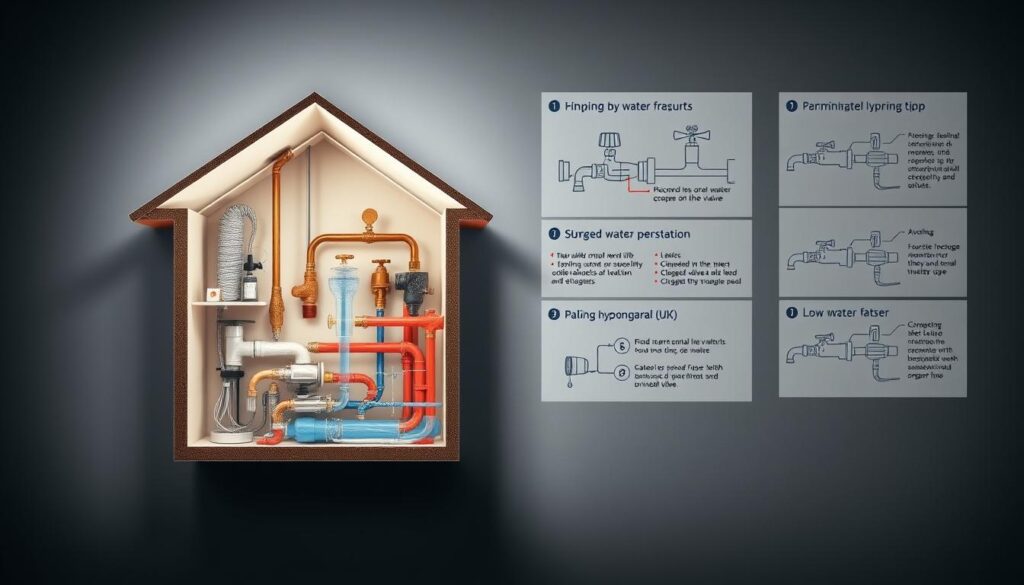

Plumbing Repair Tools for Common Household Issues

Learn More

For UK homeowners, having a well-stocked toolkit for plumbing repairs is essential for maintaining their home’s integrity and avoiding costly professional fees. Plumbing issues can arise unexpectedly, and being prepared with the right tools can make a significant difference in resolving problems efficiently.

Pipe Wrenches and Adjustable Spanners

A pipe wrench is a fundamental tool for any homeowner dealing with plumbing repairs. Its robust design and strong grip make it indispensable for handling heavy-duty tasks, such as tightening or loosening stubborn or rusted pipes. An adjustable spanner is another versatile tool that can be used for a variety of tasks, from gripping bolts to adjusting pipe fittings.

Plungers and Drain Snakes

Clogged drains are a common issue in many UK homes. A plunger is often the first line of defence, capable of clearing blockages with a bit of effort. For more stubborn clogs, a drain snake (also known as an auger) can be used to navigate deeper into the pipes and remove the obstruction.

Pipe Cutters and Joining Tools

When it comes to working with pipes made of different materials such as plastic or metal, having the right cutting and joining tools is crucial. Pipe cutters are designed to make clean, square cuts, which are essential for ensuring proper sealing and preventing leaks. For joining pipes, tools such as soldering equipment, compression fitting tools, and push-fit systems are used, depending on the pipe material and the specific application.

In conclusion, being equipped with the right plumbing repair tools can significantly simplify the process of maintaining and repairing your home’s plumbing system. Whether you’re dealing with plastic or metal pipes, having a well-stocked toolkit is key to resolving common household issues efficiently.

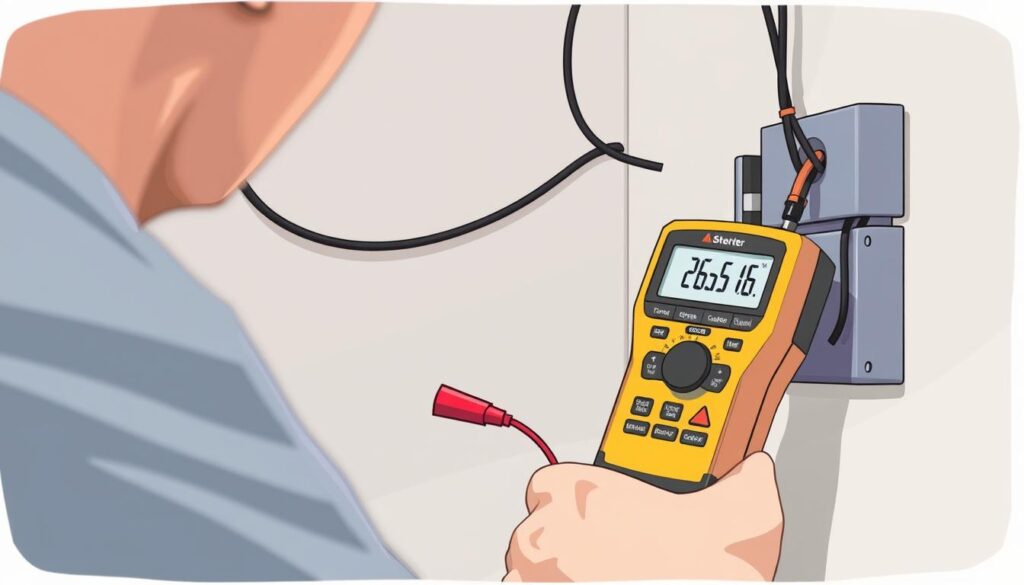

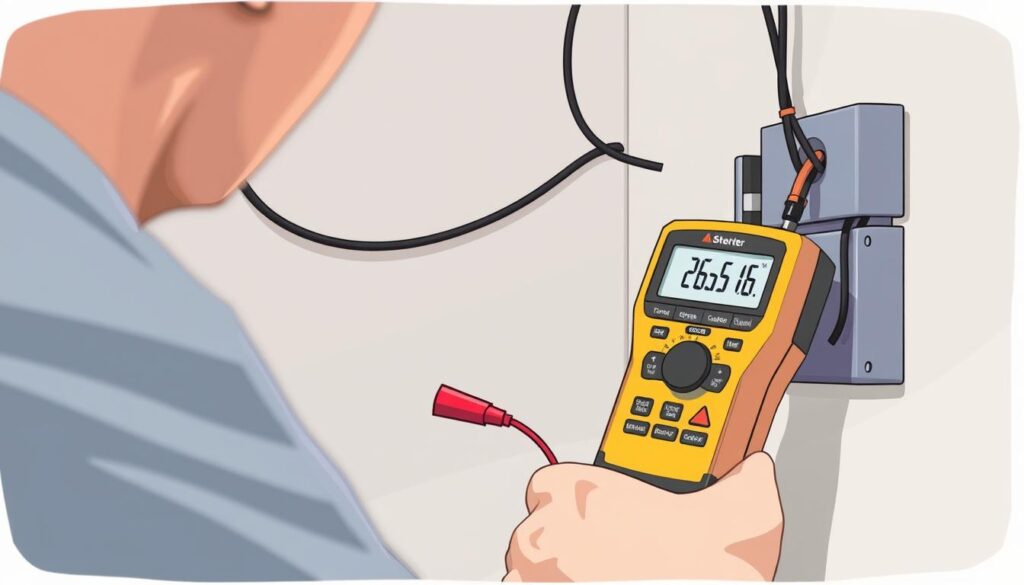

Electrical Repair Tools for Safe Home Maintenance

When it comes to electrical repairs in your UK home, having the right tools is crucial for safety and efficiency. Electrical wiring may not be your primary focus, but you’ll inevitably encounter electrical tasks like installing a new stereo or repairing a window.

Learn More

Voltage Testers and Safety Equipment

Voltage testers are essential for ensuring that electrical circuits are safe to work on. They help you detect the presence of voltage, preventing accidental shocks. When choosing a voltage tester, look for one that is non-contact, making it safer and easier to use.

For added safety, consider using a voltage tester with a high voltage rating and one that is designed for your specific needs, such as testing outlets or wiring.

Wire Strippers and Crimping Tools

The Klein11057 Klein-Kurve Wire Stripper and Cutter is a valuable tool for any electrical task. It serves two critical functions: cutting wires to the desired length and safely stripping the insulation from the wire ends. When working with electrical wiring, wire strippers and crimping tools are indispensable for making secure connections.

Insulated Screwdrivers and Pliers

For electrical work, it’s crucial to use screwdrivers and pliers that are properly insulated to prevent electrical shock. Look for tools that are VDE-certified, as they meet UK safety standards. Insulated tools are designed to protect you from electrical shock, making them a must-have for any electrical repair.

When using insulated tools, ensure they are in good condition and free from damage. Regularly inspect your tools and replace them as needed to maintain your safety while working on electrical projects.

Painting and Decorating Tools for Home Refreshes

Learn More

To achieve a professional finish, you’ll need to equip yourself with the best painting and decorating tools. Whether you’re touching up a single room or giving your entire home a fresh coat of paint, having the right equipment is crucial for a successful project.

Brushes and Rollers: Selecting the Right Types

Choosing the correct brushes and rollers is vital for a smooth, even finish. For cutting in and detailed work, use high-quality brushes with synthetic or natural bristles, depending on the type of paint you’re using. Rollers are ideal for covering large areas quickly.

Preparation Tools: Scrapers, Sandpaper, and Fillers

Before you start painting, proper preparation is key. Use scrapers to remove old paint and wallpaper, sandpaper to smooth out surfaces, and fillers to repair any cracks or holes. These tools will help ensure a professional-looking finish.

Paint Trays, Ladders, and Protective Coverings

To make your painting project efficient and safe, you’ll need the right accessories. Paint trays and scuttles help you manage paint and reduce mess. Ladders provide the necessary height, but always ensure they’re stable and secure to maintain safety. Protective coverings like dust sheets and masking tapes protect your floors and trim from unwanted paint splatters.

By investing in the right painting and decorating tools, you’ll not only achieve a professional finish but also make the work process more enjoyable and efficient.

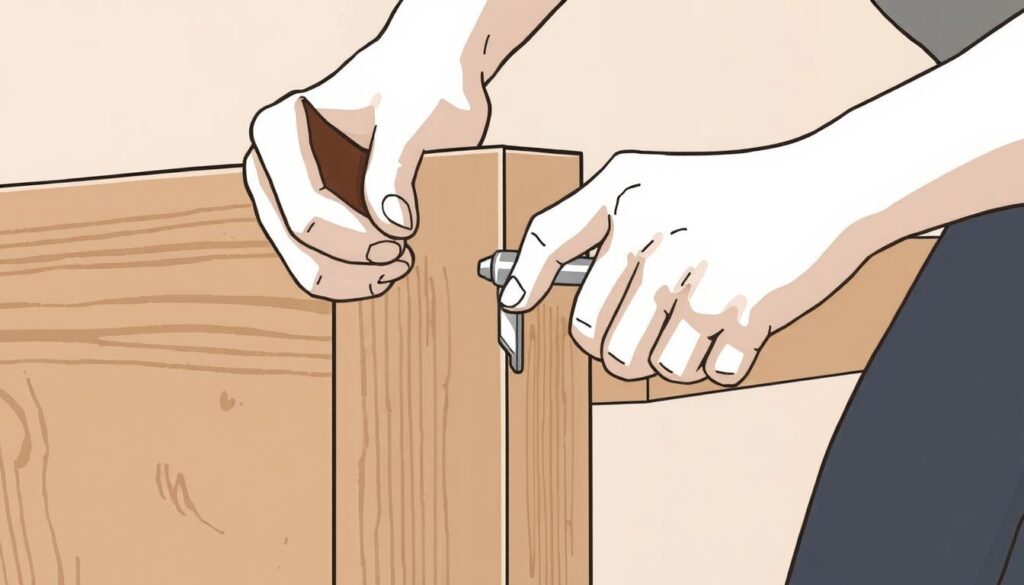

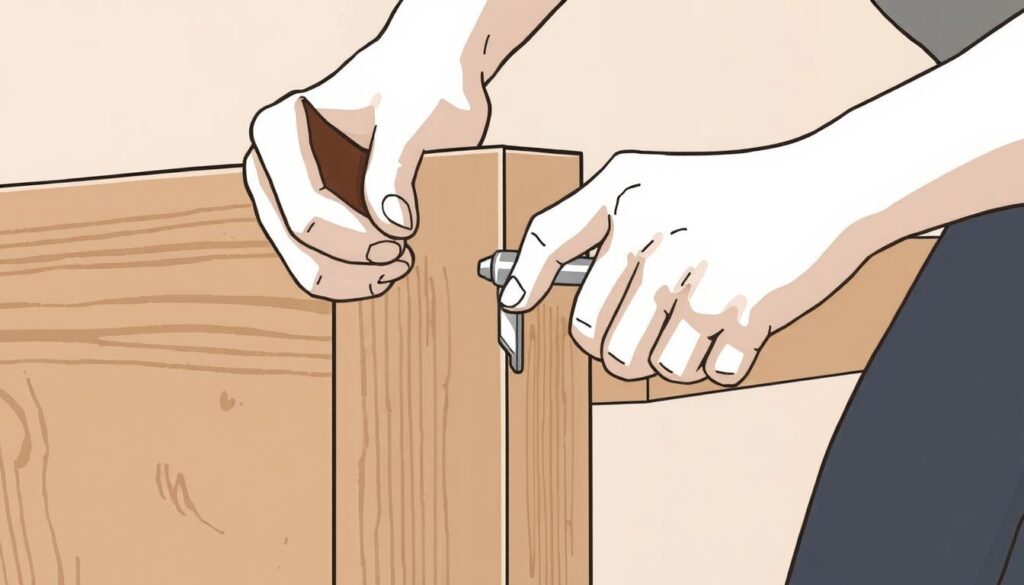

Speciality Tools for Furniture Assembly and Repair

Learn More

To tackle furniture repairs and assembly with confidence, you’ll need to have the right speciality tools on hand. Furniture assembly and repair require precision and the correct equipment to achieve professional results.

Allen Keys and Hex Wrenches

Allen keys and hex wrenches are essential for assembling and repairing furniture that uses hexagonal bolts. These tools come in various sizes and are used to drive bolts and screws with hexagonal heads. Having a set of Allen keys in different sizes will ensure you’re prepared for most furniture assembly tasks.

Clamps and Wood Glues

Clamps are vital for holding parts together while glue dries during furniture repair. Spring clamps and C-clamps are particularly useful, with the latter being available in a range of sizes to accommodate different projects. When using clamps, it’s essential to insert buffer blocks of scrap wood between the jaws and the material being clamped to avoid damage.

Furniture Repair Kits and Touch-Up Materials

Furniture repair kits are available in the UK market, offering specialised solutions for scratch repair, veneer repair, and upholstery repair. These kits usually include touch-up materials like wax sticks, markers, and fillers to address common furniture damage. Using the right repair kit can help you achieve a professional finish and extend the life of your furniture.

When repairing visible furniture surfaces, matching colours and finishes is crucial. Techniques for achieving a seamless repair include using colour-matching guides and testing touch-up materials on inconspicuous areas first. Knowing when to attempt a DIY repair versus seeking professional restoration is also important to avoid further damage.

Safety Equipment to Accompany Your Tool Collection

Learn More

As you build your tool collection, it’s equally important to consider the safety equipment that accompanies it. Ensuring your safety while working on DIY projects is paramount, and having the right safety gear can make all the difference.

Protective Eyewear and Gloves

Protective eyewear, such as safety goggles, shields your eyes from debris and chemicals. Gloves, on the other hand, provide grip, protection from cuts, and insulation against electrical shock or heat. When selecting gloves, consider the type of work you’ll be doing and choose gloves that are appropriate for the task.

Dust Masks and Respirators

Dust masks and respirators are crucial for protecting your respiratory system from dust, fumes, and other airborne contaminants. Disposable dust masks are suitable for occasional use, while respirators offer more comprehensive protection and are often used for more extensive projects or in poorly ventilated areas.

First Aid Supplies for DIY Accidents

A well-stocked first aid kit is an essential component of your safety equipment. It should include supplies for treating minor injuries, such as bandages, antiseptic wipes, and pain relievers. Additionally, consider including items specific to common DIY injuries, such as burn cream and eye wash solutions.

Organising a dedicated first aid kit for your tool storage area and knowing basic first aid procedures can significantly reduce the risk of complications from accidents. Understanding when to seek medical attention is also crucial.

Tool Storage and Organisation Solutions

A well-organised tool storage system is essential for UK homeowners who value their time and workspace. Effective storage solutions enable you to work efficiently, reduce clutter, and ensure that your tools are in good condition.

Learn More

Toolboxes and Tool Chests: Choosing the Right Size

When selecting a toolbox or tool chest, consider the size of your tool collection and the space available in your workshop or garage. A larger toolbox may offer more storage, but it may also occupy valuable space.

Consider a toolbox with dividers or trays to keep your tools organised and easily accessible. Some toolboxes also come with lockable lids for added security.

Wall-Mounted Storage Systems

Wall-mounted storage systems are ideal for maximising space in smaller workshops or garages. These systems typically consist of a pegboard or slatwall with hooks and bins to hang and store your tools.

They keep your tools organised, visible, and within easy reach, making it simpler to find the right tool for the job.

Tool Belts and Portable Organisers

For those who need to work on projects away from their workshop, tool belts and portable organisers are invaluable. They allow you to carry your essential tools with you, ensuring you’re always prepared.

Tool belts come in various designs, with some featuring multiple pockets and compartments to keep your tools organised. Portable organisers, such as tool totes or bucket systems, offer additional storage and can be easily carried to different work sites.

Budget-Friendly Tool Kits for New Homeowners

Learn More

Creating a functional tool kit on a budget is a strategic process that requires careful planning. As a new homeowner, you need to balance the quality of tools with the cost, ensuring you have the right equipment for DIY tasks without overspending.

Starter Tool Kits: What’s Included and What’s Missing

Starter tool kits are an excellent starting point for new homeowners. They usually include a basic set of tools such as a hammer, screwdrivers, and pliers. However, it’s essential to assess what’s missing from these kits to ensure you have a comprehensive tool collection.

Typically, starter kits lack specialised tools for specific tasks. You may need to supplement these kits with additional tools tailored to your needs.

Prioritising Tool Purchases on a Limited Budget

When funds are limited, prioritising tool purchases is crucial. Focus on acquiring tools that are frequently used and versatile. For instance, a good quality adjustable wrench and a set of screwdrivers can help with a variety of tasks.

Consider alternative approaches such as borrowing tools from friends or family, or exploring community tool libraries available in some UK areas. Buying second-hand tools can also be cost-effective, but be sure to inspect them for quality before purchasing.

To spread costs, plan your tool purchases around specific projects. This approach ensures you have the necessary tools when you need them, while managing your budget effectively.

You can expect to pay an average of 25 percent more for high-quality equipment, but investing in good tools can save you money in the long run by reducing the need for frequent replacements. The initial cost of a tool is just the beginning; consider the long-term value it provides to your DIY endeavours.

Maintaining and Caring for Your Repair Tools

Learn More

Ensuring your tools are well-maintained is vital for successful DIY projects. Proper care not only extends the lifespan of your tools but also ensures they perform optimally when needed.

Cleaning and Rust Prevention

Regular cleaning is essential to prevent the buildup of dirt and grime on your tools. Use a soft cloth and mild detergent to wipe down tools after use. For tools prone to rust, such as those made from steel, apply a rust-inhibiting coating or store them in a dry environment.

Sharpening Cutting Tools

Sharpening cutting tools, such as saws and knives, maintains their effectiveness. Use a sharpening stone or file appropriate for the tool material. Regular sharpening not only improves cutting performance but also reduces the risk of accidents caused by dull tools.

When to Replace Worn or Damaged Tools

Identifying when a tool is beyond repair is crucial for safety and efficiency. Signs that a tool needs replacement include excessive wear, damage to critical parts, or if the tool no longer performs its intended function. Continuing to use worn or damaged tools can lead to accidents and decreased productivity.

- We’ll identify signs that indicate a tool should be replaced rather than repaired.

- You’ll learn about safety concerns associated with continued use of damaged or worn tools.

- The subsection will discuss warranty considerations and manufacturer repair services available in the UK.

- We’ll explain how to dispose of or recycle old tools responsibly within UK waste management systems.

- The discussion will include guidance on upgrading versus like-for-like replacement when tools reach end of life.

Smart and Innovative Tools for Modern UK Homes

Learn More

The world of DIY tools is rapidly evolving, and UK homeowners can now benefit from innovative solutions that simplify home maintenance. These modern tools not only make tasks easier but also provide more accurate results, saving time and effort.

Multi-Tools and Space-Saving Designs

Multi-tools have become essential for many UK homeowners due to their versatility and space-saving design. These tools combine several functions into one device, making them ideal for a variety of tasks around the home.

Digital Measuring and Detection Tools

Digital measuring and detection tools have revolutionised the way homeowners approach DIY projects. These tools offer precise measurements and can detect hidden features behind walls, making them invaluable for home repairs.

Battery Systems and Compatibility Considerations

Battery technology has advanced significantly, impacting the performance of cordless tools. When selecting cordless tools, it’s crucial to consider the battery system and compatibility to ensure seamless integration across multiple tools.

Investing in a single battery system can offer several advantages, including reduced costs and increased convenience. Understanding battery maintenance practices, such as proper charging and storage, can maximise lifespan and performance.

When choosing cordless tools, consider the voltage and capacity required for your specific home repair needs. A higher voltage may offer more power, but it’s essential to balance this with the type of tasks you’ll be performing.

In conclusion, smart and innovative tools are transforming the way UK homeowners approach DIY projects. By understanding the benefits and considerations of these modern tools, homeowners can make informed decisions to enhance their home repair capabilities.

Conclusion: Building Your Repair Tool Collection Over Time

As you start or continue to build your tool collection, focusing on quality, versatility, and maintenance will serve you well. Creating an effective repair tool kit for your home is not a one-time task, but rather an ongoing process of refinement.

The key to a successful tool collection lies in understanding your needs and gradually acquiring the tools that will help you tackle various tasks. By prioritizing quality and appropriate selection, you’ll be able to efficiently complete repairs and maintenance tasks.

Proper maintenance of your tools is also crucial. Regular cleaning, rust prevention, and sharpening cutting tools will extend their lifespan and ensure they remain in good working condition. As you develop your tool collection, you’ll also want to develop your repair skills, allowing you to tackle more complex projects with confidence.

Approaching tool acquisition as a journey rather than a one-time purchase will help you build a well-rounded collection that meets your needs. With the right tools and knowledge, you’ll be empowered to maintain your home effectively, giving you a sense of satisfaction and empowerment.

By following these principles, you’ll be well on your way to creating a comprehensive tool kit that will serve you well for years to come, making repair tasks more manageable and less daunting.

FAQ

What are the essential drill bits to have for various home repairs?

For different materials, you’ll need a variety of drill bits, including twist bits for metal, spade bits for wood, and masonry bits for drilling into brick or concrete.

How do I choose the right wrench for a specific task?

Consider the type of job and the size of the bolts or nuts you’re working with. An adjustable wrench can be useful for various tasks, while a socket wrench provides more leverage for larger fasteners.

What safety equipment should I use when working with power saws?

Always wear protective eyewear, such as safety glasses or goggles, and consider using ear protection and a dust mask to prevent injury from debris and noise.

How do I maintain my cutting tools to ensure they remain effective?

Regularly sharpen your cutting tools, such as handsaws and utility knives, and store them properly to prevent damage and rust.

What are the benefits of using a cordless power drill?

A cordless drill offers greater flexibility and convenience, allowing you to work in various locations without being restricted by a power cord.

How do I select the right tape measure for my needs?

Consider the length and width of the tape measure, as well as its durability and resistance to wear. A 25-metre tape measure is a good all-purpose choice for most home repairs.

What plumbing repair tools are essential for common household issues?

For common plumbing tasks, you’ll need pipe wrenches, adjustable spanners, and plungers to tackle clogs and leaks.

How do I ensure accurate measurements when working on a project?

Use a level and a square to ensure your work is straight and level, and double-check your measurements with a tape measure or ruler.