Are outdated electrical outlets putting your family’s safety at risk?

If your UK home is older, it’s likely that your power outlets are outdated and may not meet current safety standards. Relying on adapters and power strips to use modern devices can be hazardous. Upgrading your home’s outlets is a manageable DIY project that can significantly improve your home’s electrical safety.

This comprehensive guide will walk you through the process of safely upgrading your home’s outlets, improving both safety and functionality. By the end of this guide, you’ll understand how electricity flows through your home’s outlets and how modern outlets provide better protection against electrical hazards.

Key Takeaways

- Identify which outlets need upgrading to improve safety.

- Understand the step-by-step installation process for new outlets.

- Learn how to select the right outlet types for different areas of your living space.

- Discover how modern outlets provide better protection against electrical hazards.

- Gain confidence in tackling this important aspect of home maintenance.

Understanding Why You Should Upgrade Your Electrical Outlets

Upgrading your electrical outlets is a crucial step in maintaining a safe and efficient electrical system in your UK home. Outdated outlets can pose significant safety risks, including electrical shocks and fires.

Signs Your Outlets Need Upgrading

If you notice any of the following signs, it may be time to upgrade your electrical outlets: two-prong outlets instead of three-prong, insufficient power outlets around the house, plugs falling out frequently, or having mobile babies or toddlers in the house. Two-slot power outlets used to be standard but aren’t grounded, missing the third wire that protects from electric shock.

Safety Benefits of Modern Outlets

Modern outlets offer substantial safety benefits, including proper grounding, protection against electrical surges, and special features designed to prevent electrical fires and shocks. Grounded outlets are much safer than ungrounded, protecting from shock and lowering the likelihood of short circuits. GFCI outlets are essential safety devices that monitor the flow of electricity and automatically cut power when they detect an imbalance.

Types of Modern Outlets Available in the UK

The UK market offers various specialised outlets, including USB-integrated outlets, weather-resistant outlets for outdoor use, and smart outlets that can be controlled remotely as part of a comprehensive smart home system. Other types include AFCI receptacles, tamper-resistant receptacles, LED nightlight outlets, recessed outlets, and pop-up outlets. Understanding the electrical panel that supports your home’s outlets is essential when planning upgrades.

Essential Tools and Materials for Upgrading Electrical Outlets

To safely upgrade your electrical outlets, you’ll need a specific set of tools and materials. Upgrading electrical outlets is a task that requires attention to detail and the right equipment to ensure safety and efficiency.

Required Tools for the Job

Having the right tools is crucial for the safe and efficient upgrade of electrical outlets. You’ll need a flathead screwdriver and a Phillips screwdriver for removing the old outlet and installing the new one. A voltage tester is essential for verifying that there’s no power supply to the outlet you’re working on. Additionally, needle-nose pliers are useful for handling wires, and electrical tape can be used for additional insulation.

Outlet Types and Materials

When selecting new outlets, consider the specific needs of each location in your home. For areas near water, such as kitchens and bathrooms, GFCI outlets are recommended due to their ground fault protection. The quality of materials also plays a significant role in safety and longevity. Choose outlets and faceplates from reputable manufacturers that meet British electrical standards.

Step-by-Step Guide to Upgrading Old Electrical Outlets

The process of upgrading old electrical outlets involves several key steps that, when followed correctly, can help you achieve a safer and more efficient electrical system in your home. Before you begin, it’s essential to understand the importance of safety and the correct procedures to follow.

Safety Preparations Before Starting

Before commencing any electrical work, ensure your safety by turning off the appropriate circuit breaker and verifying that the power is off using a voltage tester. This critical first step prevents electrical shock and is non-negotiable when working with wires in your home.

- Identify the correct circuit breaker controlling the outlet you wish to upgrade.

- Switch off the breaker and test the outlet to ensure it’s dead.

Removing the Old Outlet

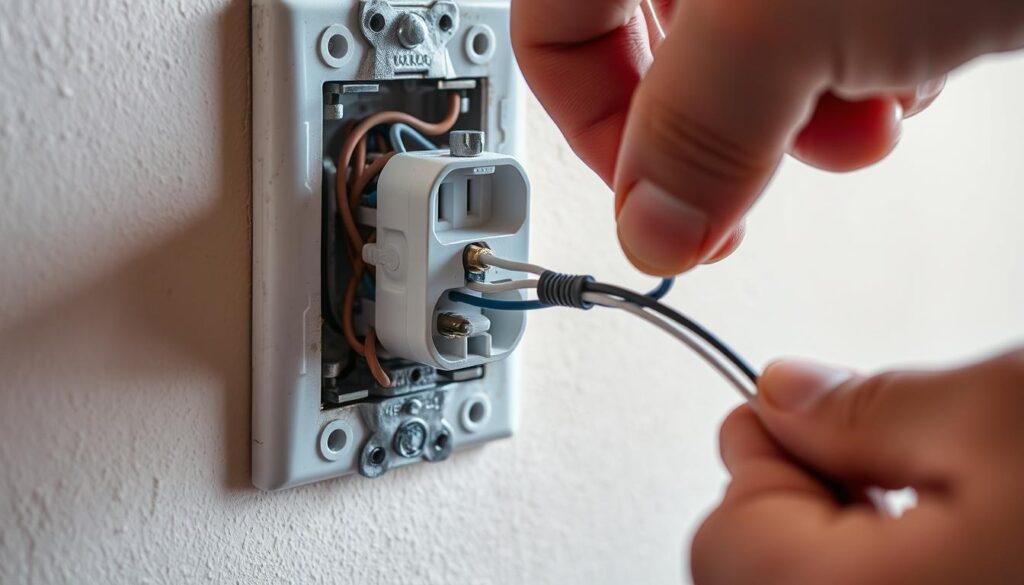

To remove the old outlet, start by unscrewing the faceplate. Once removed, you’ll see the mounting screws that attach the outlet to the junction box. Carefully unscrew these, and gently pull the outlet forward to expose the wires connected to its terminals.

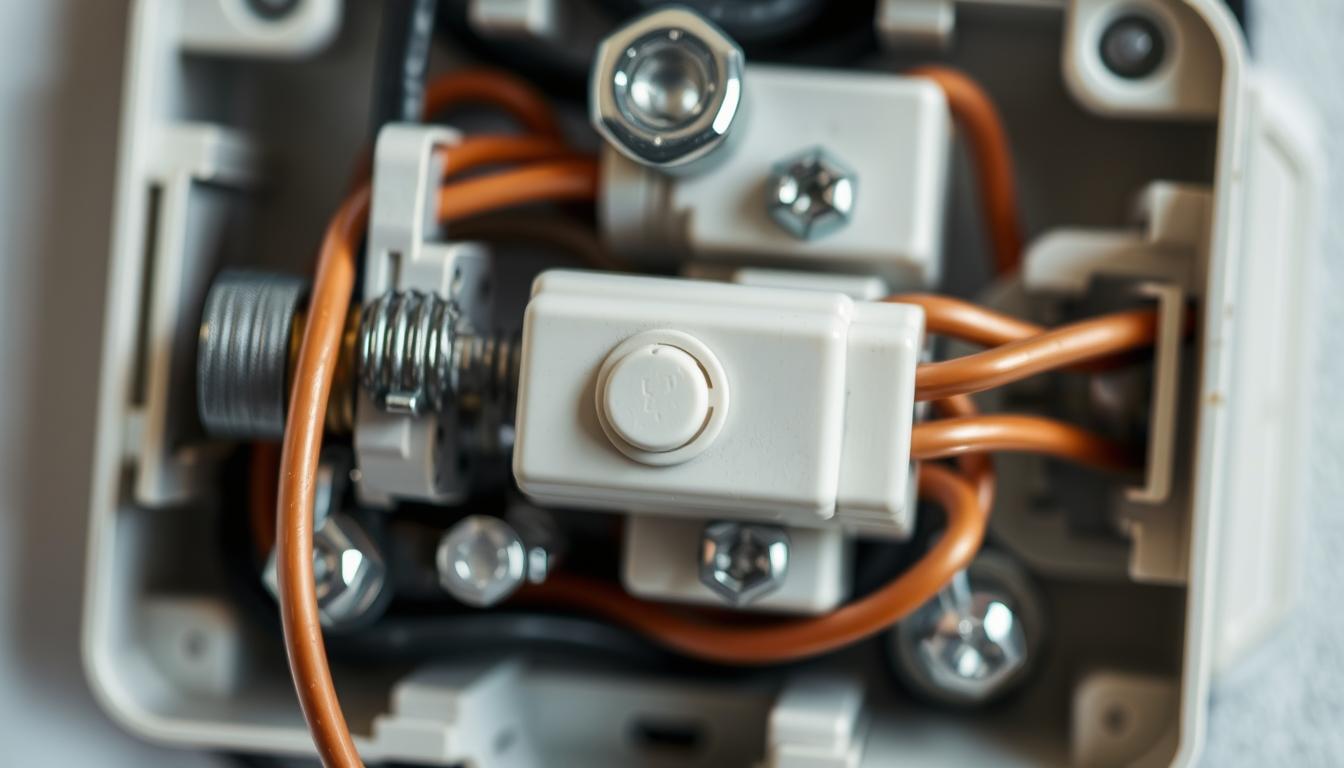

Understanding the Wiring

In UK homes, you’ll typically find three wires: the live wire (usually brown), the neutral wire (usually blue), and the earth/ground wire (green and yellow striped or bare copper). Each serves a specific purpose in the circuit. Understanding the role of each wire is crucial for a safe and correct installation.

- Live wire: Brown

- Neutral wire: Blue

- Earth/Ground wire: Green and yellow striped or bare copper

Installing the New Outlet

Connecting the Wires Correctly

To attach the new outlet correctly, connect the live wire to the brass-coloured terminal, the neutral wire to the silver-coloured terminal, and the ground wire to the green terminal. Ensure each wire is securely fastened with no loose copper strands.

- Form a clockwise hook in the wire using needle-nose pliers.

- Tighten the screw to secure the wire.

Securing the Outlet in Place

After wiring is complete, carefully fold the wires back into the junction box, taking care not to place excessive strain on any connections. Position the new outlet and secure it to the box with the mounting screws. Ensure it’s straight and flush before tightening.

Testing Your New Outlet

Once the new outlet is installed, restore power by switching the breaker back on. Test the outlet with a voltage tester or by plugging in a simple device like a lamp to confirm proper function and complete the installation process.

Conclusion: Ensuring Safety and Compliance

Upgrading your home’s electrical outlets is a vital step towards ensuring your family’s safety and bringing your property up to date with current UK electrical standards. This process is not just about modernization; it’s a crucial safety improvement that protects against electrical shocks and fires. Modern outlets, especially those with GFCI and AFCI protection, significantly reduce these risks. For complex electrical projects or whole-house rewiring, it’s advisable to consult certified electricians who understand UK electrical compliance nuances. Regular inspection of your outlets, ideally during summer, can help identify signs of wear or damage. Consider a comprehensive electrical panel assessment alongside outlet upgrades, particularly for older properties. For more information on dealing with old wiring, visit Wave Electrical Solutions. Proper documentation of your electrical work is also important for future reference or when selling your home.

FAQ

What are the signs that indicate my home’s outlets need to be replaced?

If you notice sparks, burning smells, or if your outlets feel warm to the touch, it’s likely time to replace them. Additionally, if your outlets are loose or have broken sockets, consider replacing them to ensure your home’s safety.

Can I replace my outlets myself, or do I need to hire a professional?

While it’s possible to replace outlets yourself, it’s recommended that you hire a certified electrician if you’re unsure about any aspect of the process. They can ensure the job is done safely and to the required standards.

What type of outlet should I install in my kitchen?

Kitchens require special consideration due to the presence of water and high-power appliances. Consider installing RCD-protected outlets or using a Residual Current Device (RCD) to enhance safety.

How do I know if my new outlet is installed correctly?

After installation, test your new outlet using a voltage tester to ensure it’s working correctly. You should also check that the faceplate is securely attached and that there are no signs of damage or wear.

What is the purpose of the ground wire in my outlet?

The ground wire provides a safe path for electricity to flow to the ground if there’s a fault, protecting you from electric shock. Ensure it’s properly connected when installing a new outlet.

Can I use electrical tape to secure wires?

While electrical tape can be used to insulate wires, it’s not a substitute for proper wiring practices. Use it sparingly and ensure that your wiring is secure and meets the required standards.

It’s also a good idea to wear protective eyewear when using chemical drain cleaners or when disassembling pipes to prevent injury from splashes or debris.

It’s also a good idea to wear protective eyewear when using chemical drain cleaners or when disassembling pipes to prevent injury from splashes or debris.