Are you aware of the potential risks associated with improper condensate disposal in your air conditioning or high-efficiency furnace system? Water damage can be a significant concern if not addressed properly.

Installing an automatic condensate pump is a crucial task that can mitigate such risks. This device removes water produced during the heating or cooling process, preventing damage to your home.

In this comprehensive guide, we will walk you through the process of selecting, installing, and maintaining a condensate pump for optimal performance. Whether you’re replacing an old pump or installing a new one, this step-by-step guide will help you complete the job efficiently and safely.

Key Takeaways

- Understand the importance of installing an automatic condensate pump to prevent water damage.

- Learn how to select the right condensate pump for your system.

- Follow a step-by-step guide for safe and efficient installation.

- Discover maintenance tips to ensure optimal pump performance.

- Troubleshoot common issues associated with condensate pumps.

Understanding Condensate Pumps and Their Purpose

To effectively manage the water produced by your heating and cooling system, it’s crucial to understand the role of a condensate pump. A condensate pump is a small but essential device that collects and removes water produced during normal operation.

What is a Condensate Pump?

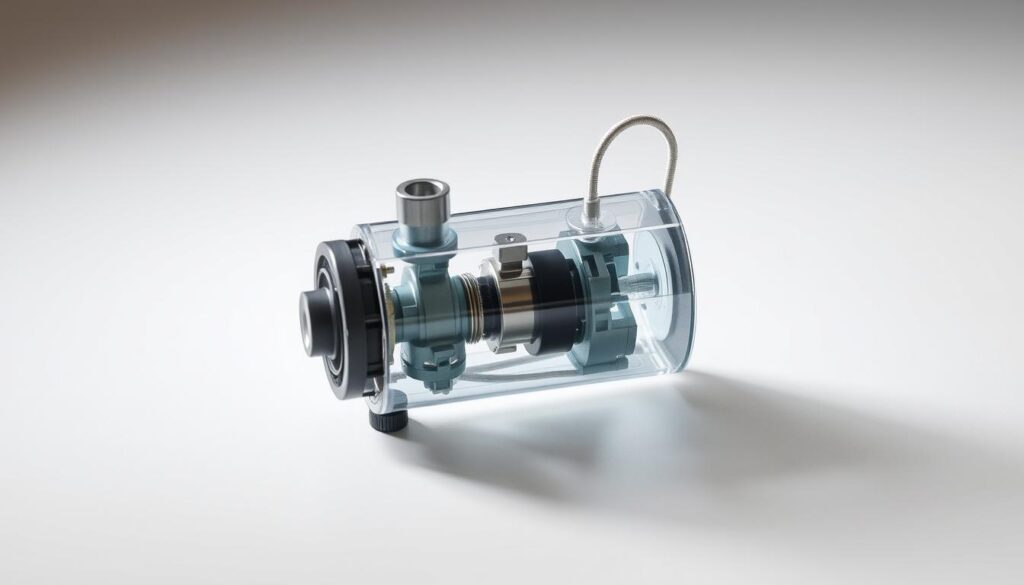

A condensate pump is essentially a little pump that sits beside your furnace or central air conditioning system. It’s about 5 x 7 x 11 inches in size and contains a small reservoir that holds around half a gallon of water. When the water level reaches a certain point, the float lifts, activating the motor to pump out the condensate.

Why Your System Might Need a Condensate Pump

Your system might require a condensate pump if you have a high-efficiency furnace, air conditioner, or heat pump that generates condensation as part of its operation. This is particularly beneficial in older homes without basement floor drains, as it provides a means to move water to a suitable drainage point.

Tools and Materials Needed for Installation

Gathering the right tools and materials is crucial for a successful condensate pump installation. Before you begin, ensure you have everything you need to avoid unnecessary delays.

Essential Tools for the Job

You’ll need a variety of tools for the installation process. These include screwdrivers (both flathead and Phillips), wire cutters/strippers, pliers, and a measuring tape. Having these tools on hand will make the process smoother.

Choosing the the Right Condensate Pump for Your System

Selecting the the right condensate pump is vital for your air conditioning system’s efficiency. Consider factors like pump horsepower, reservoir size, and voltage compatibility. Brands like Little Giant are popular for residential applications due to their reliability.

When selecting a condensate pump, you’ll also need to consider the discharge line and possibly a check valve if not included with the pump. Ensuring compatibility with your existing setup is key to a successful installation.

Safety Precautions Before You Begin

To avoid potential hazards, safety measures must be taken before installing a condensate pump. Ensuring your safety is crucial when dealing with electrical and water-related components.

Electrical Safety Measures

When installing a condensate pump, turning off the power to your furnace or air conditioning system is essential. Verify that the power is off using a voltage tester to prevent electrocution or injury. Consider installing a safety switch that can automatically shut down your system if the pump fails, providing an additional layer of protection.

Water Damage Prevention

Keep all tools and materials dry during installation. Have towels or a wet/dry vacuum handy to address any water spills promptly. Wear protective gear, including gloves, when handling old pumps that may contain stagnant water or algae buildup. Ensure your work area is well-lit and spacious enough to manoeuvre comfortably around your heating and cooling equipment.

By following these safety precautions, you can minimize risks associated with installing a condensate pump, ensuring a safe and successful installation process.

Preparing Your System for Condensate Pump Installation

Before installing a condensate pump, it’s essential to prepare your air conditioning system. This step ensures a safe and effective installation process.

Turning Off Power to Your System

Begin by turning off the power to your system at the circuit breaker. Verify with a voltage tester that no electricity is flowing to the unit. This is a crucial safety measure to prevent electrical shock or damage to the system.

Assessing Your Current Setup

Carefully assess your current setup, noting the location of drain lines and power sources. If you’re replacing an existing pump, take photos of the current installation before disconnecting anything. This will serve as a valuable reference during reinstallation.

Planning the Installation Location

Plan the installation location carefully, ensuring the pump is level and close to the air conditioning unit. The condensate pump must be installed below the coil drain to allow gravity to assist with water flow into the reservoir. Measure and plan the the route for the drain line, ensuring it has a continuous downward slope.

By following these steps, you can ensure a successful installation of your condensate pump, maintaining the efficiency and safety of your air conditioning system.

Step-by-Step Guide to Install Automatic Condensate Pump

The installation of an automatic condensate pump is a relatively simple task that can be completed with the right tools and a bit of patience. To begin, you need to understand the basic components involved and their roles in the overall functioning of your air conditioning system.

Mounting the Pump in the Correct Position

To mount the condensate pump, start by securely attaching it to the wall or floor using the built-in mounting slots and appropriate screws for your surface type. Make sure the pump is level and positioned below the coil drain to allow gravity to assist with water flow into the reservoir. Use a spirit level to verify proper positioning.

Connecting the the Drain Lines

Connect the drain line from your air conditioner or furnace to the inlet port of the condensate pump, ensuring it’s angled downward to promote proper drainage. The inlet pipe should be on an angle where it enters the the tank and should not interfere with the operation of the float valve that the pump uses.

Setting Up the Discharge Line

For the discharge line, use flexible vinyl tubing of the recommended diameter (typically 3/8″) and install it so that gravity assists with water flow when the pump is operating. It’s advisable to install a check valve on the somewhere on the the discharge line to prevent backflow of water into the pump when it’s not running.

Wiring the Condensate Pump

When it comes to wiring, you can either hardwire the pump to your system following the manufacturer’s instructions and local electrical codes or simply plug it into a nearby outlet if available. If hardwiring, carefully strip the the wires, connect them according to the colour coding, and secure all connections with wire nuts. Make sure all electrical connections are properly insulated and secured.

Testing Your Newly Installed Condensate Pump

Testing your newly installed condensate pump is a vital step to guarantee it’s operating as expected. After completing the pump installation, you need to verify that it’s functioning correctly to avoid any potential issues with your furnace or air conditioner.

Initial Power-Up and Testing Procedure

To start testing, turn power back on at the circuit breaker and run your air conditioning unit. Observe the pump to make sure it’s working correctly. The most effective method to test the condensate pump is by slowly pouring room temperature water into its reservoir until it reaches the activation level.

What to Look for During Testing

As you pour water into the reservoir, watch carefully as the pump activates, typically when the reservoir is about two-thirds full. Ensure that the discharge line properly expels water and that there are no leaks. Listen for any unusual noises during operation—a properly functioning pump should run relatively quietly with minimal vibration.

After the initial test, run your air conditioner or furnace for several cycles to ensure the condensate pump activates and deactivates correctly under normal operating conditions. Check all connections again after the system has run for a while to catch any potential leaks.

Troubleshooting Common Installation Issues

Troubleshooting is essential when dealing with condensate pump installations. Even with careful planning, issues can arise that affect the performance of your system. Understanding how to identify and resolve these problems is crucial for maintaining efficiency and preventing potential damage.

Pump Not Activating

If your pump isn’t activating, first check that it’s receiving power. Ensure the electrical connections are secure and that there are no issues with the power supply. Next, inspect the float mechanism for any obstructions or debris that might prevent proper movement. Sometimes, the float can get stuck due to dirt or improper alignment.

Water Leakage Problems

Water leakage is another common issue that can occur. Typically, this stems from loose connections at the drain lines or discharge tubing. To resolve this, ensure all connections are tight and properly sealed. Check the condition of the pipes and fittings for any signs of damage or wear.

Unusual Noises or Vibrations

Unusual noises or vibrations often indicate that the pump isn’t level or that there’s an obstruction in the impeller. Disconnect power and inspect the pump thoroughly. Ensure it’s properly aligned and that there are no blockages in the air intake or discharge.

Addressing Siphoning Issues

Siphoning issues can occur when the discharge line rises above and then drops below the source of condensation, creating a vacuum effect. To prevent this, consider installing an anti-siphoning device or air break in the drain hose. This is particularly important when the discharge line must run at varying elevations to avoid obstructions.

By addressing these common issues, you can ensure your condensate pump operates efficiently and effectively, maintaining the overall performance of your system.

Conclusion

The successful installation of your condensate pump marks the beginning of a worry-free experience with your HVAC systems. To ensure the longevity and efficiency of your condensate pump, regular maintenance is crucial. Make sure to keep the reservoir clean and consider using algae-preventing tablets like Pan Tablets No. AC-912 to prevent clogs.

Proper installation and maintenance will protect your home from water damage and ensure the efficient operation of your air conditioning and furnace systems. By following these guidelines, you can enjoy a reliable and long-lasting pump that safeguards your home’s heating and cooling systems.

Remember, a correctly installed pump can last many years, while installation errors often lead to premature failure. By making sure to select the right pump for your system and maintaining it properly, you can prevent potential issues and ensure optimal performance.